A group of scientists at the University of Minnesota Twin Cities has created a significant new impetus for innovation that shifts from sustainable materials such as trees and corn to the key synthetics, acrylic corrosive and acrylates, which are used in paints, coatings, and superabsorbent polymers. The new impetus innovation is likewise profoundly effective, and that implies lower costs for assembling sustainable synthetics.

The new impetus plan shifts from lactic corrosive-based synthetics to acrylic corrosive and acrylates with the best return to date.The innovation shows considerably better execution when benchmarked against different classes of driving impetuses.

The examination is distributed online in the JACS Au.

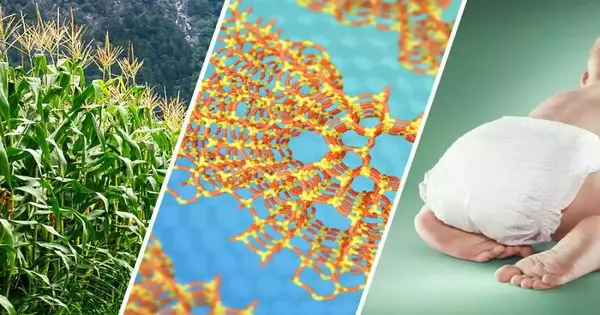

The general public is generally acquainted with acrylic corrosive and related acrylates through their purposes in everyday things, from paints and coatings to tacky glues and superabsorbent materials utilized in diapers. These synthetics and materials have been made for the last 100 years from petroleum products. However, in recent years, the corn industry has expanded beyond food and animal feed to include the production of useful synthetics.

“Our new catalyst formulation finding yields the best yield of acrylic acid from lactic acid to date. We compared the performance of our new catalyst to all existing catalysts, and it much outperforms previous instances.”

Paul Dauenhauer, professor in the University of Minnesota.

One such chemically determined compound is possible lactic corrosive, a critical component in the production of sustainable and compostable plastics used in a variety of everyday applications.

Lactic acid can also be completely converted to acrylic acid and acrylates using catalysts. Nonetheless, prior to this new impetus disclosure, traditional impetuses were wasteful, achieving low yields and making the overall cycle prohibitively expensive.

“Our new impetus plan disclosure accomplishes the best return to date for acrylic corrosive from lactic corrosive,” said Paul Dauenhauer, teacher in the College of Minnesota Branch of Compound Designing and Materials Science. “We benchmarked the exhibition of our new impetus against every earlier impetus, and the presentation far surpasses past models.”

The new impetus plan considerably lessens the expense of assembling sustainable acrylic corrosion and acrylates from corn by further developing yield and decreasing waste. Interestingly, this could lessen the cost of sustainable acrylic corrosion beneath fossil-inferred synthetics.

Lkril Innovations, a new business that intends to make minimally expensive sustainable acrylic corrosive and acrylates, is pursuing the monetary open door created by the new impetus.Lkril Advances will foster innovation outside the lab by allowing the impetus for innovation from the College of Minnesota.

“Compound assembling has depended on a class of impetuses called “zeolites” for 50 years,” says Dr. Chris Nicholas, Chief of Lkril Advances. “Because the new impetus disclosure is based on a zeolite plan that is already available at scale, our new cycle to make acrylic corrosive and acrylates will achieve minimal expense with okay.”

At the College of Minnesota, the examination group intends to proceed with their essential exploration and impetus plan to comprehend the key parts of the science with monetary help from the Middle for Feasible Polymers settled at the College of Minnesota.

“This is a great illustration of how tending to significant essential examination questions that are at the core of key catalysis can prompt creative new cycles that have genuine mechanical commitment,” said Marc Hillmyer, head of the Middle for Feasible Polymers and a teacher in the College of Minnesota Branch of Science.

“A significant test in the Middle for Feasible Polymers is the efficient and practical conversion of biomass to polymer fixings, and this work addresses a significant solution to that challenge that will have a long-term impact.”

More information: Yutong Pang et al, Multifunctional Amine Modifiers for Selective Dehydration of Methyl Lactate to Acrylates, JACS Au (2023). DOI: 10.1021/jacsau.2c00513