Manufactured polymers are everywhere in our general public—from nylon and polyester apparel to Teflon cookware and epoxy sticks. At the sub-atomic level, these polymers’ particles are made of long chains of monomer building blocks, the intricacy of which increases the usefulness of numerous such materials.

Specifically, copolymers, which comprise various kinds of monomers in a similar chain, consider tweaking the material’s properties, said Peng Chen, the Peter J.W. Debye Teacher of Science in the School of Expressions and Sciences (A&S). Monomer grouping assumes a basic role in a material’s properties; however, researchers up to this point have come up short on a strategy for sequencing engineered copolymers.

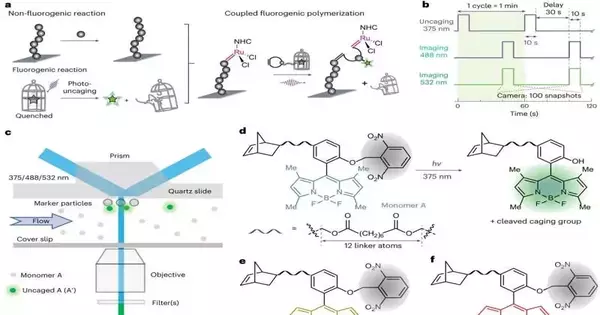

Chen and partners have created CREATS (Coupled Response Approach Toward Super-Goal Imaging), which permits them to picture polymerization catalysis responses at the single-monomer goal and, through fluorescent motioning, to separate monomers from each other. Both are significant stages in finding the sub-atomic piece of a manufactured polymer.

“Every monomer that goes in gives off a puff of light, A laser induces the light, and the puff of light has color. In our case, the choice is between green and yellow. We can tell what monomer goes in by whether it is yellow or green.”

Peng Chen, the Peter J.W. Debye Professor of Chemistry in the College of Arts and Sciences (A&S).

They depict the method and the principal disclosures they’ve made with it in “Optical Sequencing of Single Engineered Polymers,” distributed in Nature Science.

The co-lead creators are Rong Ye, Xiangcheng Sun, and Xianwen Mao, all previous postdoctoral scientists in the Chen bunch. Co-creators are previous Chen bunch postdoctoral analysts Susil Baral and Chunming Liu, ebb and flow postdoctoral scientist Felix Alfonso, and Geoffrey Coates, the Tisch College Teacher in Science and Synthetic Science (A&S).

“Manufactured polymers are made of monomer units connected together like a series of globules,” Chen said. In the least difficult polymers, the monomers are indistinguishable; however, more mind-boggling properties emerge when polymers contain monomers of various sorts—called copolymers. The exact plan of the monomers in a copolymer assumes a significant role in its properties, like solidity or adaptability.

Succession assumes a part in the properties of regular polymers as well, Chen said. A protein, for instance, is made of 20 amino-corrosive monomers organized in an unmistakable succession.

“In a characteristic polymer, nature has control,” Chen said. “In manufactured polymers, people are making the game plans, and the physicists, for the most part, don’t have that exact control.”

Sequencing copolymers is so troublesome to a great extent in light of heterogeneity in manufactured polymers, Chen said. Individual chains vary in length, structure, and arrangement, which requires single-polymer sequencing strategies that can determine and distinguish individual monomers.

A few present-day techniques permit researchers to control the plan of monomers in a chain, Chen said, but only for extremely short polymers—10 to 20 monomers in length.

Utilizing CREATS, the scientists can determine the succession of a polymer as it is made, each monomer in turn, by imaging and recognizing each and every monomer as it is added to the polymer. To make the monomers noticeable, CREATS couples the polymerization response with another response that produces fluorescent signs.

“Each monomer that goes in radiates a puff of light,” Chen said. “The light is incited by a laser, and the puff of light has a variety. For our situation, it’s either green or yellow. By seeing whether it’s yellow or green, we see what monomer goes in.”

The lab is now prepared to quantify manufactured polymer properties. Now that they can decide the grouping of a singular polymer, a subsequent stage is to consolidate the two examinations to correspond to construction and capability, eventually giving core values to the polymer plan to accomplish specific properties.

“In the event that you realize how succession controls property, you can truly contemplate planning anything grouping you need to accomplish a specific property,” Chen said. “This information can probably assist people in tailoring their materials for an ideal application.”

More information: Rong Ye et al, Optical sequencing of single synthetic polymers, Nature Chemistry (2023). DOI: 10.1038/s41557-023-01363-2