When temperatures soar, a blast of cold air from an air conditioner can be a welcome relief. However, “A/C” units use a lot of energy and can leak harmful greenhouse gases. A plant-based film that cools down when exposed to sunlight and comes in a variety of textures and bright, iridescent colors is now being reported by scientists as an eco-friendly alternative. The material might one day be able to cool cars, buildings, and other structures without using electricity.

At the American Chemical Society’s (ACS) spring meeting, the researchers will present their findings. The ACS Spring 2023 meeting is a hybrid that will be held online and in person from March 26 to 30.

Silvia Vignolini, Ph.D., the project’s principal investigator, states, “To make materials that remain cooler than the air around them during the day, you need something that reflects a lot of solar light and doesn’t absorb it, which would transform energy from the light into heat.” “Adding color pigments would typically reverse their cooling effects because there are only a few materials that possess this property,” Vignolini adds.

“To create materials that stay cooler than the air surrounding them during the day, you need something that reflects a lot of solar radiation rather than absorbs it, which would convert the light’s energy into heat,”

Silvia Vignolini, Ph.D., the project’s principal investigator.

The ability of a surface to release its own heat into space without being absorbed by the air or atmosphere is known as passive daytime radiative cooling (PDRC). The end result is a surface that can become several degrees colder than the air around it without the use of electricity. Materials with this effect can help reduce the use of air conditioning and other energy-intensive cooling methods on buildings and other structures.

According to Qingchen Shen, Ph.D., who is presenting the work at the meeting, some paints and films that are currently in development can achieve PDRC; however, the majority of them are white or have a mirrored finish. Shen and Vignolini both attend Cambridge University (UK). However, a building owner who desired blue-colored PDRC paint would be out of luck because colored pigments, by definition, only reflect the colors we see and absorb specific wavelengths of sunlight, resulting in undesirable warming effects.

However, color can be achieved without the use of pigments. Cleanser stains, for instance, show a crystal of various tones on their surfaces. These varieties result from the manner in which light cooperates with varying thicknesses of the air pocket’s film, a peculiarity called primary tone. A portion of Vignolini’s research focuses on determining the causes of various natural structural colors. Her team discovered that, in one instance, cellulose nanocrystals (CNCs), which are made from plant cellulose, could be made into iridescent, colorful films without adding any pigment.

It turns out that cellulose is also one of the few naturally occurring substances that can promote PDRC. After Vignolini heard one of the first researchers to create a cooling film material speak, he realized this. “Wow, this is really amazing, and I never really believed cellulose could do this,” I thought.

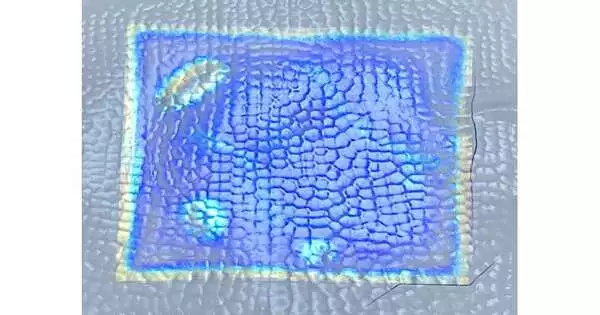

Shen and Vignolini recently created a colorful bi-layered PDRC film by layering colorful CNC materials with a white ethyl cellulose material. They made films with dynamic blue, green, and red tones that, when set under daylight, were a normal of almost 40 F cooler than the encompassing air. The film’s 120 watts of cooling power per square meter was comparable to that of many residential air conditioners. Shen says that the most difficult part of this research was figuring out how to stick the two layers together. On their own, the CNC films were brittle, and the ethyl cellulose layer needed to be plasma-treated to stick well. But the end result was strong films that could be made in a standard manufacturing line several meters at a time.

The researchers have been enhancing these first films’ aesthetic appearance ever since they were made. They are creating cellulose-based cooling films that are glittery and colorful using a technique that has been modified from approaches that the group has previously explored. According to Shen, they have also changed the ethyl cellulose film so that it has different textures, similar to the different kinds of wood finishes used in architecture and interior design. People would have more options for incorporating PDRC effects into their homes, businesses, automobiles, and other structures thanks to these modifications.

Now, the researchers want to figure out how to make their films even more useful. Shen says that CNC materials can be used as sensors to detect changes in the weather or pollutants in the environment. This could be useful if their CNC-ethyl cellulose films can also cool down. A cobalt-colored PDRC on the façade of a building in an urban area with a lot of cars, for instance, could one day keep the building cool and include detectors that would notify authorities of higher levels of smog-causing molecules in the air.

More information: ACS Spring 2023: Structurally colored radiative cooling cellulosic films, www.acs.org/meetings/acs-meetings/spring-2023.html