Because of their low harmfulness, compound strength, and amazing electrical and optical properties, carbon-based nanomaterials are tracking an ever increasing number of uses across gadgets, energy change and capacity, catalysis, and biomedicine. Carbon nano-onions (CNOs) are surely no exemption. First detailed in 1980, CNOs are nanostructures made out of concentric shells of fullerenes, looking like enclosures inside confines. They offer various alluring characteristics, like a high surface region and huge electrical and thermal conductivities.

Sadly, the regular techniques for creating CNOs have a few serious downsides. Some require cruel working conditions like high temperatures or vacuums, while others request a ton of significant investment. A few methods can evade these limits, but they call for complex impetuses, costly carbon sources, or risky acidic or essential circumstances. This enormously restricts the capability of CNOs.

Luckily, not everything trusted is lost. In a new report distributed in Green Chemistry, a group of researchers from the Nagoya Institute of Technology in Japan tracked down a basic and helpful method for transforming fish squander into very great CNOs. The group, which included Assistant Professor Yunzi Xin, Master’s understudy Kai Odachi, and Associate Professor Takashi Shirai, fostered a blend course in which fish scales removed from fish squander subsequent to cleaning are changed over into CNOs in only seconds through microwave pyrolysis.

“We may be able to create large-area emissive flexible films and LED devices thanks to the stable optical properties. These discoveries will provide new directions for the creation of solid-state lighting and next-generation displays.”

Dr. Shirai

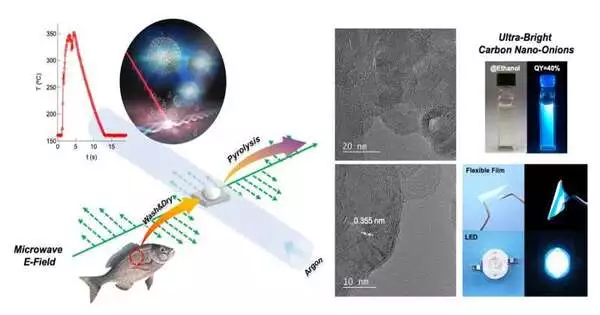

Yet, how might fish scales be changed into CNOs with such ease? While the specific explanation isn’t entirely clear, the group accepts that it has to do with the collagen contained in fish scales, which can retain sufficient microwave radiation to create a quick climb in temperature. This prompts warm decay, or “pyrolysis,” which creates specific gases that help the gathering of CNOs. What’s amazing about this approach is that it doesn’t require any perplexing impetuses, cruel circumstances, or long wait times; the fish scales can be converted into CNOs in under 10 seconds!

(Left) Diagram depicting the union of carbon nano-onions via microwave pyrolysis of fish scales.The top inset shows the climb in temperature of the fish scales because of microwave retention over a time of 10 seconds, as well as a proposed development system for the carbon nano-onions. (Right) transmission electron microscopy pictures showing the morphology of the blended carbon nano-onions and photos of CNO scattering in ethanol, an emissive adaptable film, and a LED containing CNO.

Also, this blend cycle yields CNOs with high crystallinity. This is strikingly hard to accomplish in processes that utilize biosquander as a starting material. Also, during blend, the outer layer of the CNOs is specifically and completely functionalized with (COOH) and (OH) gatherings. This is a glaring difference to the outer layer of CNOs arranged with regular techniques, which is normally exposed and must be functionalized through extra advances.

This “programmed” functionalization has significant ramifications for the use of CNOs. At the point when the CNO surface isn’t functionalized, the nanostructures will generally stay together, inferable from an alluring connection known as pipi stacking. This makes it hard to scatter them in solvents, which is vital in any application requiring arrangement-based processes. In any case, since the proposed union cycle produces functionalized CNOs, it is considered to have great dispersibility in different solvents.

One more benefit related to functionalization and the high crystallinity is that of uncommon optical properties. Dr. Shirai makes sense of the fact that “the CNOs show super splendid apparent light outflow with a proficiency (or quantum yield) of 40%.” This value, which has never been accomplished, is multiple times higher than that of recently revealed CNOs blended through regular strategies. “

To demonstrate some of the numerous possible applications for their CNOs, the group demonstrated their use in LEDs and blue-light-radiating slim films. The CNOs created a profoundly steady outflow, both inside strong gadgets and when scattered in different solvents, including water, ethanol, and isopropanol. “The stable optical properties could empower us to create huge regions of emissive adaptable movies and LED gadgets,” guesses Dr. Shirai. “These discoveries will open up new roads for the improvement of cutting-edge showcases and strong-state lighting.”

Besides, the proposed union method is harmless to the ecosystem and gives a clear method for changing over fish squander into vastly more helpful materials. The group accepts that their work would add to the satisfaction of a few of the UN’s Sustainable Development Goals. Also, assuming CNOs advance into cutting-edge LED lighting and QLED shows, they could enormously assist with lowering their assembling costs.

More information: Yunzi Xin et al, Fabrication of ultra-bright carbon nano-onions via a one-step microwave pyrolysis of fish scale waste in seconds, Green Chemistry (2022). DOI: 10.1039/d1gc04785j

Journal information: Green Chemistry