From economical mass items to custom-fitted super advanced materials, our cutting-edge world without plastics is incomprehensible. The significant disadvantage to this is the utilization of non-renewable energy sources and the increasing amounts of waste. Another methodology could be the development of high-grade plastics produced using biomass that could be made to self-destruct into recyclable parts. The “destruct order” would be given in light of a particular frequency, as exhibited by specialists in the journal Angewandte Chemie.

Biomass is an inexhaustible, frequently tremendously modest, unrefined substance that is progressively of interest for the development of superior-execution plastics. Bio-based plastics, on the other hand, face the issue of inadmissible reusing.Plastics need to remain dependably stable while they are being used, without the gamble of untimely disintegration. Reusing ought to, in a perfect world, be upcycling as opposed to downcycling. The structure blocks delivered ought to be convertible to another top-notch material. In an ideal world, these eventual monomers could be polymerized again to produce similarly superior performance plastics.

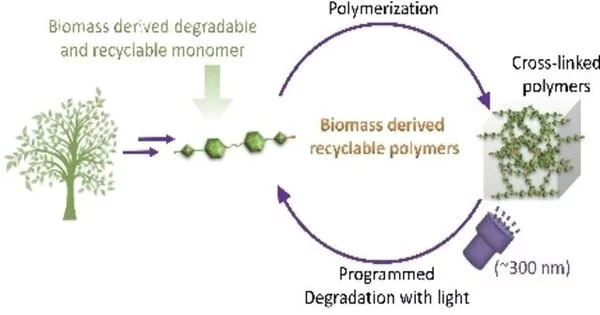

To address this difficulty, an interdisciplinary group of specialists from the United States — Jayaraman Sivaguru at the Center for Photochemical Sciences, Bowling Green State University in Bowling Green, Ohio, and Mukund P. Sibi and Dean C. Webster at North Dakota State University in Fargo — have picked bio-based plastics for which debasement can be set off by illumination with light. They had the option to create crosslinked polymers that contain building blocks in their spine in light of vanillin. For example, vanillin can be delivered from material, for example, lignin, which is a side-effect of cellulose creation.

The vanillin subordinate created by the group assimilates light at 300 nm and goes into an invigorated state. This prompts a substance response that sets off the corruption of the polymer. Since this frequency isn’t held back in that frame of mind of daylight that arrives on the earth, spontaneous debasement is stayed away from. The specialists had the option to recuperate 60% of the monomers, which could be polymerized again without any deficiency in value.

Photodegradable, recyclable, and inexhaustible crosslinked polymers made of biomass assets are an exceptionally encouraging methodology for delivering more maintainable plastics. Light-set off debasement is harmless to the ecosystem and offers the benefit of spatial and transient control.

More information: Ravichandranath Singathi et al, Towards Upcycling Biomass‐Derived Crosslinked Polymers with Light, Angewandte Chemie International Edition (2022). DOI: 10.1002/anie.202203353