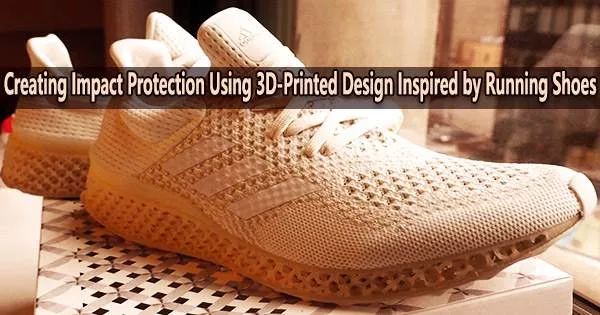

The concept of a 3D-printed product, which might help shield structures from collision damage and other high-impact pressures, comparable to a car traveling at 60 km/hr, was inspired by a substance used in running shoes and memory foam pillows.

Published in Smart Materials and Structures, Dr. Tatheer Zahra from the QUT Centre for Materials Science and QUT School of Civil and Environmental Engineering used off-the-shelf bioplastic to 3D print geometric shapes that mimic the behaviour of auxetic materials.

“Rather than flattening when stretched or bulging when compressed, auxetic materials expand or contract in all directions at once, which makes them highly energy-absorbent and load-resistant,” Dr. Zahra said.

“But existing commercial auxetic material is expensive and not locally available, so I designed geometric shapes that achieved the same behaviour.”

According to Dr. Zahra, auxetic geometries produced through 3D printing have the ability to take the role of steel and fiber-reinforced polymer mesh reinforcements in composites. They might also be utilized as a versatile and extensively used protective wall render.

According to her, the energy absorption would be comparable to a 20 mm thick reinforced composite protective render applied to a full-scale building wall, which could be able to withstand the force of an oncoming car traveling at 60 km/hr.

Rather than flattening when stretched or bulging when compressed, auxetic materials expand or contract in all directions at once, which makes them highly energy-absorbent and load-resistant. But existing commercial auxetic material is expensive and not locally available, so I designed geometric shapes that achieved the same behaviour.

Dr. Tatheer Zahra

“At scale, composites embedded with these geometries could theoretically resist high impact or shock energy caused by gas explosions, earthquakes and wind forces, and car collisions.”

“In Australia, there’s an estimated 2000 vehicular crashes each year. Direct building damage cost at 2.5 per cent would put the damage bill at about $38.65M/year for housing.”

“Since vehicles also crash into apartments, office building, restaurants, and convenience stores, this cost of building damage would probably be higher.”

“Loss of life would be the highest cost.”

Dr. Zahra said protection for masonry walls was especially important because it was an essential part of most commercial and residential buildings.

“Masonry is a very cheap material that is resilient to noise, heat, and has better fire protection properties compared to wood or steel, but its mortar joints weaken the overall structural strength.”

“If auxetic geometries were embedded into the mortar to make protective composites, they would also be protected from microorganisms and temperatures over 60°C, and should last the design life of the structure,” she said.

Proven at lab scale, Dr. Zahra now aims to test the designs on full-scale masonry and concrete structures at the QUT Banyo Pilot Plant.

“The designs would be good prospects for commercialisation through additive manufacturing because the production process is flexible and materials are readily available,” Dr. Zahra said.

“3D printing would also allow us to change the material, size or design of geometric shapes to suit different structures and load requirements.”

Dr. Zahra said bioplastics provided a more sustainable, low-carbon emission alternative to fibre-reinforced plastic or other non-biodegradable polymers.

She added that using auxetic materials, which might cost up to $400 per square metre and were not biodegradable, was more expensive.