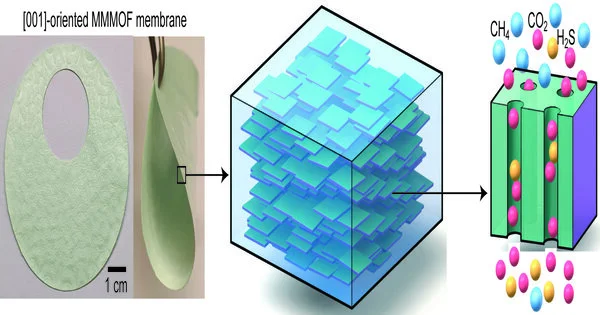

Particular evacuation of inconvenient gases, for example, hydrogen sulfide (H2S) and carbon dioxide (CO2) from gaseous petrol (CH4) could be made simpler and more powerful by utilizing another type of situated blended network metal-natural structure (MMMOF) layer created at KAUST, which could enable better utilization of this cleaner non-renewable energy source.

The upsides of film innovation over conventional division (e.g., cryogenic refining and adsorptive detachment) are that it is energy-proficient and more straightforward to work with. Blended lattice layers (MMMs) shaped by implanting particular adsorbents in a persistent polymer framework address an engaging mix of the adsorbents and simple handling of polymers.

“The in-plane alignment of MOF nanosheets inside the polymer matrix, as well as the successful translation of adsorbent unique separation properties into a processable matrix, is groundbreaking,”

Shuvo Datta

“Our accomplishment of in-plane arrangement of MOF nanosheets inside the polymer framework and fruitful interpretation of adsorbent unmistakable detachment properties into a processable network is progressive,” says Shuvo Datta.

MOFs are half-breed natural inorganic materials that contain metal particles or groups held together by natural atoms known as linkers. Shifting these parts permits scientists to make a reasonable pore-opening that licenses particular sorption or potentially greater dissemination of one gas over one more in light of their size.

“These glass-like materials are challenging to process into a deformity-free situated film, but we fostered a straightforward arrangement projecting strategy to handle them,” says Mohamed Eddaoudi.

Regular MMMs frequently go through nanoparticle-polymer interface inconsistency, and channels or pores of adsorbents are arbitrarily situated to hamper the gas partition. To keep away from those restrictions, MMMOF films were considered and built-in view of three interlocked measures:

- (I) a fluorinated MOF (KAUST-8), as a sub-atomic sifter adsorbent that specifically upgrades H2S and CO2 dispersion while barring CH4;

- (ii) fitting MOF precious stone morphology into nanosheets with maximally uncovered 1D channels and advancing a nanosheet-polymer communication; and

- (iii) in-plane arrangement of nanosheets in a polymer lattice and fulfillment of the consistently situated MMMOF layer.

The MMMOF film exhibited far superior H2S and CO2 division from flammable gas under reasonable working circumstances (e.g., high tension, high temperature, delayed season of 30 days, and so on) compared with traditional MMMs.

“Truth be told, this centimeter-scale adaptable situated layer can be viewed as a solitary piece of an adaptable precious stone in which a large number of MOF nanosheets are consistently adjusted in a predefined crystallographic heading and the holes between adjusted nanosheets are loaded up with polymer. “It’s the first of its kind,” says Shuvo Datta.

“I think that this disclosure will most likely motivate researchers in the scholarly world and industry to investigate different reasonable films to address various modern energy-serious partitions,” says Mohamed Eddaoudi.

The review is published in Science, and the group presently needs to proportional its strategy to exhibit its business potential. They will likewise look to apply it to other significant modern gas division processes.