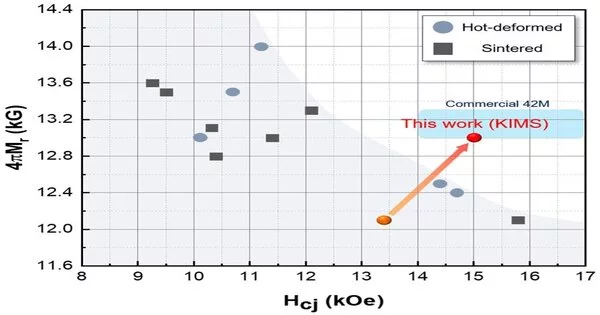

Dr. Jung-Goo Lee and Dr. Tae-Hoon Kim of the Korea Institute of Materials Science (KIMS), a government-funded research institute under the Ministry of Science and ICT, led a research team to develop rare-earth-saving permanent magnets that can replace 42M-graded commercial magnets while reducing the amount of neodymium (Nd), an expensive rare-earth material, by about 30%. Even though the number of high-priced rare-earth minerals was reduced, the technique achieved the commercial level of performance currently employed in the industry.

Although neodymium is a pricey and insecurely available metal, it is required for the production of rare-earth permanent magnets. Instead of reducing the percentage of Nd, the content of Ce (a cheap element) was raised in order to generate an Nd-reduced permanent magnet. Until recently, loss of magnetic characteristics was unavoidable as Ce content rose. The study team concentrated on determining the origin and process of the loss of magnetic characteristics induced by increased Ce content, and they were able to tackle the problem of rare-earth-reduced permanent magnets by manipulating the atomic-scale microstructure.

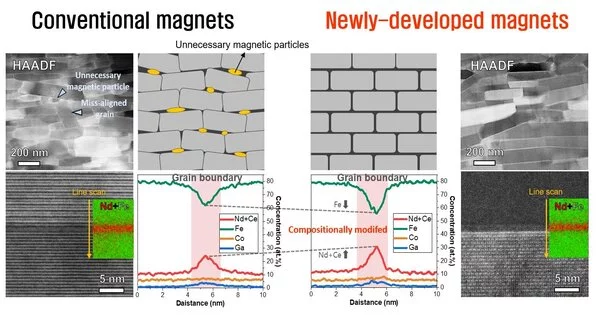

The researchers discovered that throughout the production process, superfluous magnetic particles were created, which were the cause of the magnets’ magnetic and microstructural qualities deteriorating. They altered the microstructure and improved magnetic characteristics by inhibiting atom diffusion, which prevents the creation of unwanted magnetic particles.

The researchers used the melt-spinning approach and the hot-deformation method to fabricate rare-earth-reduced precursors and final bulk magnets, respectively. Both methods have very fast cooling rates compared to the standard process. As a result, they were able to optimize the magnets’ microstructure by preventing the creation of unwanted magnetic particles. Furthermore, they were able to concurrently improve residual magnetization and coercive force, which are two of permanent magnets’ most important qualities.

In 2021, the domestic market for rare-earth permanent magnets for high-efficiency motors was valued at $186 billion per year, and Korea is reliant on imports. Localization of rare-earth permanent magnet materials is vital for Korea, given contemporary challenges such as China’s weaponization of rare-earth resources, Japan’s export limitations on magnetic materials, and global carbon neutrality. When this technology is commercialized, it can be employed in high-value-added businesses that demand high-efficiency motors, such as electric automobiles, drones, flying cars, and electric ships.

The research team was directed by Dr. Tae-Hoon Kim, a senior researcher at KIMS. When the technology is commercialized, it will address the domestic rare-earth permanent magnet markets’ resource challenges as well as issues with materials, parts, and equipment. This is just the start. With further research, we will make every effort to lead the growth of the domestic rare earth permanent magnet industry in the future.

On March 17, the findings of the study were reported in Scripta Materialia.