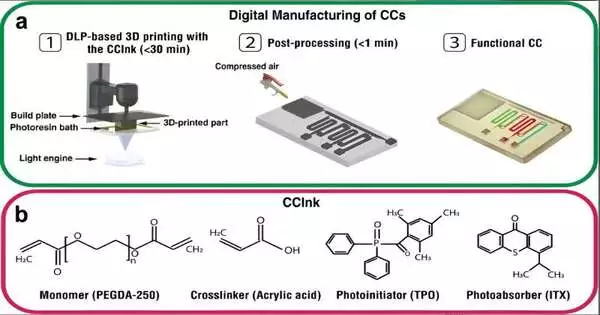

McGill College scientists have made a forward leap in demonstrative innovation, creating a “lab on a chip” that can be 3D-imprinted in only 30 minutes. The chip can possibly make on-the-spot testing generally open.

As a feature of a new report, the consequences of which were distributed in the diary Progressed Materials, the McGill group created capillaric chips that go about as scaled-down research centers. Not at all like other PC microchips, these chips are single-use and require no outside power source; a basic paper strip gets the job done. through hairlike activity, the very peculiarities by which a spilled fluid on the kitchen table unexpectedly wicks into the paper towel used to wipe it up.

“Conventional diagnostics require peripherals, while our own can bypass them. Our diagnostics are a cycle of what the PDA was to conventional personal computers that expected a different screen, console, and power supply to work,” makes sense of Prof. David Juncker, Seat of the Branch of Biomedical Designing at McGill and senior creator on the review.

“Traditional diagnostics require peripherals, whereas ours can do without. Our diagnostics are similar to what a cell phone was to traditional desktop computers, which required a separate display, keyboard, and power source to function.”

Prof. David Juncker, Chair of the Department of Biomedical Engineering at McGill.

At-home testing became critical during the coronavirus pandemic. Yet, fast tests have restricted accessibility and can drive one fluid across the strip, meaning most diagnostics are not yet finished in focal labs. Outstandingly, the capillaric chips can be 3D-printed for different tests, including coronavirus counter-acting agent evaluation.

The review brings 3D-printed home diagnostics one bit closer to the real world; however, a few difficulties remain, like administrative endorsements and getting important test materials. The group is effectively attempting to make their innovation more open, adjusting it for use with reasonable 3D printers. The development expects to accelerate analysis, improve patient consideration, and usher in another time of open testing.

“This progression has the ability to enable people, specialists, and ventures to investigate additional opportunities and applications in a more savvy and easy-to-understand way,” says Prof. Juncker. “This advancement likewise holds the possibility to ultimately engage wellbeing experts with the capacity to make custom-made answers for explicit necessities right at the mark of care quickly.”

More information: Vahid Karamzadeh et al. Digital Manufacturing of Functional Ready-to-Use Microfluidic Systems, Advanced Materials (2023). DOI: 10.1002/adma.202303867