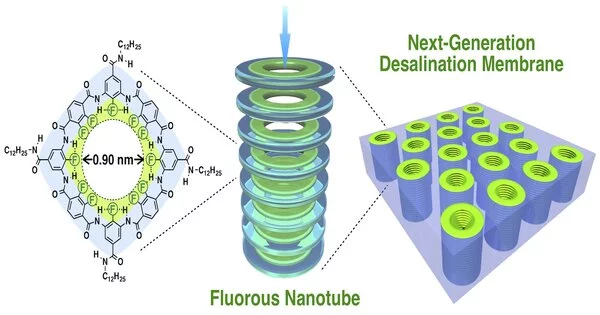

Water shortages are a developing issue all over the planet. Desalination of seawater is a laid out technique to deliver drinkable water, yet it comes with gigantic energy costs. Interestingly, specialists use fluorine-based nanostructures to channel salt from water effectively. Compared with current desalination techniques, these fluorous nanochannels work quicker, require less tension and less energy, and are a more powerful channel.

In the event that you’ve at any point cooked with a nonstick Teflon-covered skillet, you’ve most likely seen the way that wet fixings slide around it without any problem. This happens on the grounds that the critical part of Teflon is fluorine, a lightweight component that is normally water-repellent, or hydrophobic. Teflon can also be used to line lines to work on water progression.Such conduct caught the eye of Associate Professor Yoshimitsu Itoh from the Department of Chemistry and Biotechnology at the University of Tokyo and his group. It motivated them to investigate how lines or channels produced using fluorine could work on a totally different scale, the nanoscale.

Credit: © 2022 Itoh et al.

“We were interested in perceiving how compelling a fluorous nanochannel may be at specifically separating various mixtures, specifically, water and salt. Furthermore, “Consequent to running some complicated virtual experiences, we concluded it merited the time and work to make a functioning example,” said Itoh. “There are two fundamental ways of desalinating water at present: thermally, utilizing intensity to vanish seawater so it consolidates as unadulterated water; or by switch assimilation, which utilizes strain to drive water through a layer that squares salt. The two strategies require a great deal of energy, but our tests propose fluorous nanochannels require little energy and have different advantages as well. “

The group made test filtration films by synthetically orchestrating nanoscopic fluorine rings, which were stacked and implanted in a generally impermeable lipid layer, like the natural particles that make up cell dividers. They made a few test tests with nanorings between around 1 and 2 nanometers. For reference, a human hair is right around 100,000 nanometers wide. To test the viability of their films, Itoh and the group estimated the presence of chlorine particles, one of the significant parts of salt—the other being sodium—on one or the other side of the test layer.

“We wanted to determine how successful a fluorous nanochannel was at selectively filtering different chemicals, specifically water and salt. And, after some extensive computer calculations, we determined that it was worth the time and effort to develop a working sample.”

Associate Professor Yoshimitsu Itoh from the Department of Chemistry and Biotechnology

“It was exceptionally invigorating to see the outcomes firsthand.” “The more modest of our test channels impeccably dismissed approaching salt atoms, and the bigger channels were also as yet an improvement over other desalination procedures and, surprisingly, state-of-the-art carbon nanotube channels,” said Itoh. “What was of genuine amazement to me was the means by which the interaction happened so quickly.” Our example worked around a few thousand times quicker than commonplace modern gadgets, and multiple times quicker than trial carbon nanotube-based desalination gadgets. “

For example, as fluorine is electrically regrettable, it repulses negative particles, for example, the chlorine viewed as in salt. Yet, a special reward of this antagonism is that it additionally separates what are known as water bunches, basically inexactly bound gatherings of water particles, so they go through the channels much more quickly. The group’s fluorine-based water desalination films are more viable, quicker, require less energy to work, and are made to be exceptionally easy to use, too, so what’s the trick?

In any case, this is the type of thing we want to improve in the upcoming exam.” more, given the life span of the films and their low functional expenses, the general energy costs will be a lot lower than with current techniques,” said Itoh. “Different advances we wish to make are obviously increasing this. Our test tests were single nanochannels, yet with the assistance of different trained professionals, we were able to make a film around 1 meter across in quite a long time. In line with these assembling concerns, we’re additionally investigating whether comparable films could be utilized to decrease carbon dioxide or other unwanted byproducts delivered by industry. “

The outcomes are published in Science.