In a survey paper as of late distributed in the Journal of Nuclear Materials, Prof. Haug Qunying from the Hefei Institutes of Physical Science (HFIPS) of the Chinese Academy of Sciences, along with colleagues, has presented the most recent turn of events and techniques on combination energy in China and checked on the advances of decreased actuation ferritic/martensitic (RAFM) steel for designing applications.

China is completing broad combination tasks to advance the last use of clean combination energy. The test cover module (TBM) of the global nuclear exploratory reactor (ITER) is an important component for confirming energy extraction, tritium expansion, and self-maintenance.underlying materials of combination reactors are expected to meet the brutal working climate, for example, high-energy neutron illumination, high intensity transition influence, and complex electromagnetic and mechanical burdens.

“The research and development of RAFMs and TBMs has helped advance the core technologies extremely swiftly. With these advanced technologies and experiences, several associated standards have been released, and we are getting closer to the actual engineering use of RAFM steel in the ITER, CFETR, and DEMO.”

Prof. Huang Qunying

“RAFM steel enjoys many benefits,” said Prof. Huang Qunying, “such as low initiation, great radiation opposition, and high-temperature mechanical properties, as well as somewhat mature modern innovations.” That is the reason it was picked as a promising primary material for ITER-TBM and the combination DEMO reactor. “

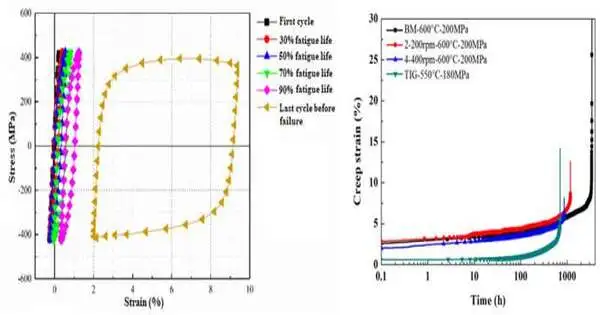

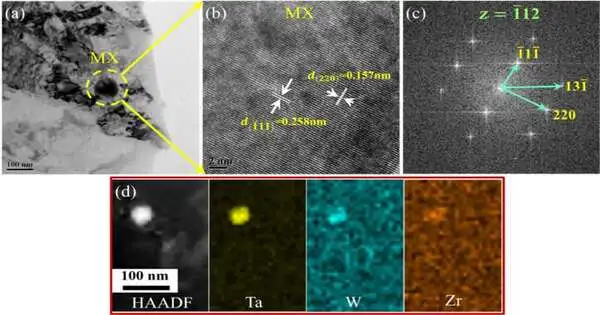

In this paper, they summarized the improvements in properties and key advancements for conclusive application in ITER and CFETR in China over the last few years.The most recent examinations and advances are fundamentally centered around creation plans, radiation obstruction and mechanical properties streamlining, handling and shaping innovations, normalization development, and designing capability.

Among them, Prof. Huang referenced the main one. “The key advancements have been pushed forward rapidly under the backing of the innovative work of RAFMs and TBM.” “With these significant advancements and experiences, we are getting closer to the last designed use of RAFM steel in ITER, CFETR, and DEMO,” she said.

These investigations lay the groundwork for a strong material and specialized starting point for the creation of ITER-TBM. They likewise give a significant reference to the innovative work of other RAFMs, ITER-TBMs, and the sweeping modules of CFETR and DEMO.

More information: Qunying Huang et al, Development of reduced activation ferritic/martensitic steels in China, Journal of Nuclear Materials (2022). DOI: 10.1016/j.jnucmat.2022.153887