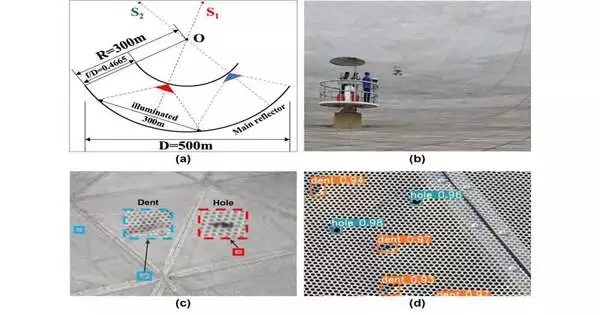

The 500-meter Gap Round Radio Telescope (Quick), otherwise called the China Sky Eye, is the world’s biggest single-dish radio telescope. Its reflector is a halfway circle of span R=300 m. The planar, halfway round cap of the reflector has a width of 519.6 m, 1.7 times bigger than that of the previously biggest radio telescope.

The huge reflecting surface makes Quick the world’s most touchy radio telescope. It was utilized by stargazers to notice, interestingly, quick radio barges in the Smooth Way and to recognize in excess of 500 new pulsars, multiple times the total number of pulsars distinguished by different telescopes around the world. Really intriguing and colorful items may yet be found using Quick.

Nonetheless, a bigger reflecting surface is more inclined to outer harm because of natural elements. The Quick reflector is made up of 4,450 joined three-sided aluminum boards with uniform holes to reduce weight and wind influence.Falling items (e.g., during outrageous occasions, for example, rockfalls, serious windstorms, and hailstorms) may cause extreme marks and openings in the boards. Such deformities unfavorably influence the investigation of low-frequency radio waves, which requires an ideal dish surface. Any anomaly in the parabola disperses these little waves from the concentration, causing data misfortune.

The quick location of surface deformities for an ideal fix is thus basic for keeping up with the typical activity of Quick. This is generally finished through direct visual review. Gifted auditors move up the reflector and outwardly analyze the whole surface, looking for and supplanting any boards showing marks and openings.

Nonetheless, this system has a few limitations. To begin with, there is an inherent risk in reaching difficult-to-reach locations high above the ground.Second, examining so many boards is a serious and time-consuming task.Third, the method depends intensely on the auditors’ skill and is inclined to human-based blunders and irregularities.

The solution for the weaknesses of manual review at Quick is robotized assessment. In another paper distributed in Light: High Level Assembling, a group of researchers led by Teacher Jianan Li and Tingfa Xu from the Beijing Foundation for Innovation have made the most vital move towards robotizing the review of Quick by coordinating profound learning methods with drone innovation.

As an initial step, the examination group coordinated profound learning methods with the utilization of robots to naturally identify deserts on the reflector surface. In particular, they started by physically controlling a robot furnished with a high-goal RGB camera to fly over the surface along a foreordained course. The camera captured and recorded recordings of surface conditions during the flight.

One advantage of the high-level flight strength of robots is that the recorded recordings can catch a ton of data about surface subtleties. Also, on account of the GPS gadget and the RTK module installed on the robot stage, each video edge can be labeled with the corresponding drone area with centimeter-level exactness. As a result, the actual areas of the boards that show up at each edge cannot be fixed.

They presented a basic yet viable cross-combination activity for profound locators, which totals staggered highlights in a guide-wise specific way toward assisting with identifying imperfections of various scales and types, to deal with the difficulties of finding surface deformities in drone symbolism showing huge scope variety and high between-class likeness.The cross-combination strategy is lightweight and computationally effective, which are especially important elements for installed drone applications.

Future work will execute the calculation on inserted equipment stages to handle captured recordings installed by the robot, to make the review framework more independent and stronger.

More information: Jianan Li et al, Automated optical inspection of FAST’s reflector surface using drones and computer vision, Light: Advanced Manufacturing (2022). DOI: 10.37188/lam.2023.001