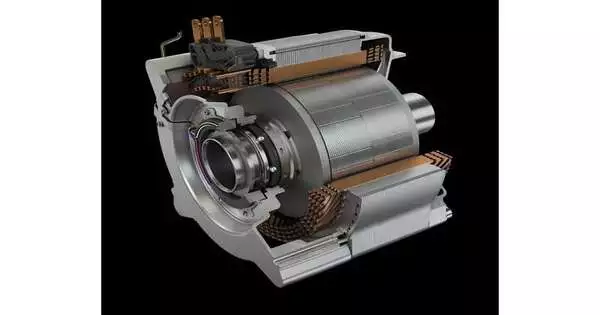

A rising number of electric vehicles are being sold, thus raising the number of delivered electric engines. Toward the end of their valuable lives, these electric engines are destroyed and then reused. The singular parts and congregations can’t be reused. Up until this point, there has been an absence of practical maintenance techniques for remanufacturing and reusing electric engines as a feature of a cutting-edge round economy.

In the REASSERT project, analysts at the Fraunhofer Foundation for Assembling Designing and Computerization (IPA) are working closely with industry accomplices to seek out different ideas for fixing, remanufacturing, and reusing electric engines, as well as new plans for the round economy.

The jolt of the powertrain is persistently advancing. The electric engines utilized contain important unrefined substances, for example, copper, as well as uncommon earth metals like neodymium, where China holds a semi-syndication, and which can’t be recovered with flow reusing techniques. Subsequently, expanding the utilization period of the engines is progressively significant. Besides, the unrefined components utilized have a greater carbon impression than a burning motor. Along these lines, it is essential to broaden the utilization period of these engines.

“We want to create a closed-loop system in which valuable resources are reused in order to eliminate reliance on raw material imports and reduce raw material extraction.”

Julian Große Erdmann, scientist at the Fraunhofer Institute for Manufacturing Engineering and Automation IPA in Bayreuth.

“Creative worth maintenance methodologies offer huge potential for discharge decreases concerning maintainability,” says Julian Große Erdmann, researcher at the Fraunhofer Establishment for Assembling Designing and Robotization IPA in Bayreuth. As a feature of the REASSERT project, scientists are teaming up with Schaeffler (consortium pioneer), the Karlsruhe Organization of Innovation, Brilliant Testing GmbH, iFAKT GmbH, and Riebesam GmbH and Co. KG to foster imaginative strategies for remanufacturing electric engines and reusing them in vehicles.

They center around the worthwhile maintenance procedures of reuse, fix, remanufacture, and natural substance reusing. These are key components for a round economy, empowering the decrease of normal asset utilization and the minimization of waste.

Diminishing ecological effect

As of now, reusing unrefined components is the established maintenance methodology. Through one or more manual or mechanized reusing strategies, materials, for example, copper and aluminum, are specifically recuperated. Electric footing engines are dismantled, destroyed, arranged into individual material divisions, and broken down for this reason. Be that as it may, the reused material, which is frequently sullied, can at this point not be utilized for engine applications, and individual parts and congregations are obliterated. Thusly, natural substance reusing ought to just be picked if all else fails for reusing and supplanted by great-value safeguarding systems, for example, reuse, fix, remanufacturing, and material reusing.

“We need to lay out a shut-circle framework in which significant assets are reused to kill reliance on unrefined substance imports and to limit unrefined substance extraction,” makes sense of Große Erdmann. The venture accomplices characterize reuse as reusing the whole motor for optional use and fixing as the substitution of faulty parts and assemblies. In “remanufacturing,” all parts are dismantled, cleaned, reconditioned, and reassembled.

“With these procedures, less natural substances like intriguing earths, copper, and others are required, maybe just for spare parts,” the scientist explains. For unrefined substance reusing, the undertaking accomplices intend to dismantle the engine and sort the singular materials preceding destroying. The undertaking accomplices are utilizing reference engines from the traveler vehicle area to break down and select which esteem maintenance systems ought to be utilized in a given application.

Building a cycle from inbound examination to end-of-line testing

The venture includes laying out a total interaction, each step of which flaunts its own demonstrator and test rig—from inbound review for engine characterization to dismantling, demagnetization, cleaning, part determination, and remanufacturing, the whole way through to reassembly and end-of-line testing, where the engine’s usefulness is evaluated.

“For example, during this interaction, an engine lodging with minor wear may be characterized for reuse and, if fundamental, reconditioned utilizing machining cycles to guarantee usefulness. Contingent upon the chosen esteem conservation system, different interaction steps and chains are involved, so the work for reconditioning may change,” makes sense to the architect.

An illustration of one of the difficulties of this would be dismantling and reusing the attractive materials from engines. “A rotor with long-lasting magnets is challenging to dismantle into its parts, even in a manual dismantling process, because of the covering and holding of the magnets. Here, the objective is to lay out non-damaging dismantling strategies.”

A simulated intelligence-dynamic instrument assists with the determination of a valuable maintenance technique.

A computer-based intelligence instrument created as a component of the venture assists with choosing the best maintenance system for a given application. It approaches the item and cycle information for the electric engine, which are saved in a computerized twin.

The information assembled in the venture is expected to be utilized for the development of new electric engines. The objective is to foster a model engine for the round economy that can be effectively dismantled and onto which the four referenced esteem conservation techniques can be easily applied.

Provided by Fraunhofer-Gesellschaft