A group of energy analysts led by the University of Minnesota Twin Cities has developed a gadget that electronically changes one metal so it acts like one more for use as an impetus in compound responses. The gadget, called a “reactant condenser,” is quick to exhibit that elective materials that are electronically changed to give new properties can yield quicker, more effective compound handling.

The advancement paves the way for new reactant advancements utilizing non-valuable metal impetuses for significant applications, for example, storing environmentally friendly power, producing infinite energy, and fabricating sustainable materials.

The exploration is distributed online in JACS Australia, where it was chosen as an Editor’s Choice distribution. The group is also working with the University of Minnesota Office of Technology Commercialization and has a temporary patent on the gadget.

“Atoms don’t want to modify their amount of electrons, This offers up a completely new avenue for manipulating chemistry and making common materials behave like precious materials.”

Paul Dauenhauer, a MacArthur Fellow and professor of chemical engineering and materials science at the University of Minnesota,

Synthetic handling for the last century has depended on the utilization of explicit materials to advance the assembling of synthetic substances and materials we use in our regular day-to-day existence. A considerable lot of these materials, like the valuable metals ruthenium, platinum, rhodium, and palladium, have extraordinary electronic surface properties. They can go about as well as the two metals and metal oxides, making them basic for controlling compound responses.

The overall population is presumably generally acquainted with this idea according to the increase in robberies of exhaust systems on vehicles. Exhaust systems are significant in view of the rhodium and palladium inside them. Palladium can be more costly than gold, as a matter of fact.

These costly materials are frequently hard to come by around the world and have turned into a significant barrier to innovation.

Credit: Dauenhauer Group, University of Minnesota

To foster this technique for tuning the synergist properties of elective materials, the analysts relied on their insight into how electrons act at surfaces. The group effectively tested the hypothesis that adding and eliminating electrons to one material could transform the metal oxide into something that emulated the properties of another.

“Particles truly don’t have any desire to change their number of electrons, yet we created the reactant condenser gadget that permits us to tune the quantity of electrons at the outer layer of the impetus,” said Paul Dauenhauer, a MacArthur Fellow and teacher of substance designing and materials science at the University of Minnesota who drove the examination group. “This opens up a completely new chance for controlling science and making bountiful materials behave like valuable materials.”

The synergist condenser gadget utilizes a blend of nanometer movies to move and settle electrons at the outer layer of the impetus. This plan has the novel instrument of joining metals and metal oxides with graphene to empower a quick electron stream with surfaces that are tunable for science.

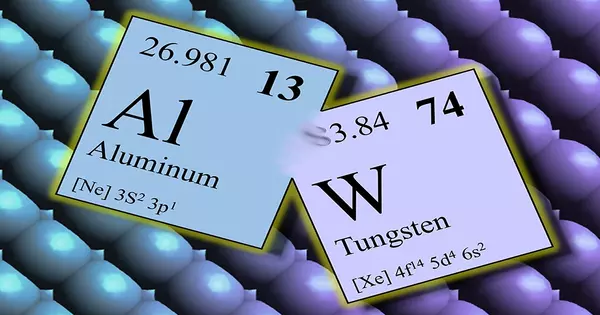

Utilizing different slight film innovations, we consolidated a nano-scale film of alumina produced using plentiful aluminum metal with graphene, which we were then ready to tune to assume the properties of different materials,” said Tzia Ming Onn, a post-doctoral specialist at the University of Minnesota who created and tried the reactant condensers. “The significant capacity to tune the reactant and electronic properties of the impetus surpassed our assumptions.”

The reactant condenser configuration has wide utility as a stage gadget for a scope of assembling applications. This adaptability comes from nanometer creation and integrates graphene as an empowering part of the dynamic surface layer. The force of the gadget to settle electrons (or the shortfall of electrons called “openings”) is tunable with the shifting organization of an unequivocally protecting inward layer. The gadget’s dynamic layer can likewise consolidate any base impetus material with extra added substances, which can then be tuned to accomplish the properties of costly reactant materials.

“We view the synergist condenser as a stage innovation that can be carried out across a large group of assembling applications,” said Dan Frisbie, a teacher and head of the University of Minnesota Department of Chemical Engineering and Materials Science and exploration colleague. “The center plan experiences and novel parts can be changed to practically any science we can envision.”

The group intends to proceed with their examination of reactant condensers by applying it to valuable metals for probably the main manageability and ecological issues. A few equal tasks are now underway to store sustainable power as smelling salts, produce the critical atoms in inexhaustible plastics, and clean vaporous waste streams.