In the computer game Minecraft, everything including creatures and characters is made of little 3D blocks called voxels. Materials researchers at the College of Virginia School of Designing and Applied Science have fostered a Minecraft-like, voxelated approach that involves drops as the fundamental structure blocks to make confounded structures equivalent to human tissues and organs.

Liheng Cai, an associate teacher of materials science and designing, substance designing and biomedical designing, drives the group. Jinchang Zhu, a Ph.D. understudy in Cai’s Delicate Biomatter Research facility, fosters their bioprinting strategy, computerized get together of round bio-ink particles (DASP).

“On a basic level, DASP permits us to unequivocally characterize the area, organization and properties of individual drops and gather them into 3D builds that match the masterfulness of natural tissues,” Zhu said.

“An analogous case is the classic tablecloth-pulling trick, in which the tablecloth is abruptly pulled away, leaving plates on the table due to inertia force. However, in our technique, the droplet is detached from the nozzle primarily due to confinement force from the supporting matrix.”

Jinchang Zhu, a Ph.D. student in Cai’s Soft Biomatter Laboratory,

Utilizing a tweaked 3D printer, the group expels and stores bio-ink beads inside a supporting framework, a slurry shower that backings and holds the drops in 3D space. The beads puff up, come into contact with their adjoining drops, and afterward set to frame a 3D grid structure. With blends of beads made of different materials or embodied with different parts, DASP shows an enormous number of opportunities for planning and making utilitarian tissue builds.

Zhu first-wrote the group’s unique paper distributed October 2021 in Cutting edge Utilitarian Materials, where Cai and his associates demonstrated the idea of voxelated bioprinting.

“The paper we distributed last year was an initial move toward 3D printing tissue with the intricacy and association required for biomedical designing, drug screening and infection demonstrating,” Cai said.

Zhu and Cai were welcome to share their most recent examination, All-watery Printing of Viscoelastic Beads in Yield-stress Liquids, in a September 2022 exceptional issue of Acta Biomaterialia.

In this latest paper, they make sense of the system for controlling a viscoelastic drop in what’s known as a yield-stress supporting lattice: The supporting network acts like a heap of sand, which resembles a strong when left undisturbed however streams like a fluid under pressure.

One interesting component of this entire printing process is that both the bio-ink drops and the supporting framework are watery; there is for all intents and purposes no strain at the limits between the beads and the general climate. The bio-ink is profoundly thick like honey, yet is flexible while being twisted at quick rates.

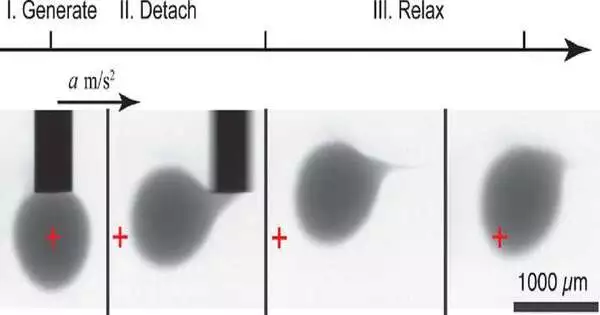

Zhu and Cai screen the elements of the entire bioprinting process progressively and recognize three included stages: drop age, separation and unwinding. As the drop is expelled, the spout moves evenly at a high speed increase to withdraw from the drop, abandoning the drop and caught inside the supporting grid.

“A closely resembling case is the traditional decorative spread pulling stunt, in which the decorative liner is pulled away unexpectedly, overlooking plates because of dormancy force,” Zhu expressed, “Yet in our procedure, the drop is segregated from the spout for the most part because of the constrainment force from the supporting lattice.”

The group additionally distinguished boundaries that generally influence the printing goal including the drop width, spout measurement and spout speed increase. Their investigations demonstrate that printing beads of good constancy requires a moderately huge drop to-spout breadth proportion and a reasonable spout speed increase up to ten meters each square second.

“Exact control of viscoelastic voxels addresses both a basic and mechanical test in delicate matter science and 3D bioprinting,” Cai said. “We are right toward the starting to lay out the essential science for voxelated bioprinting. What’s more, we trust one day we can totally make an interpretation of the Minecraft way to deal with 3D bioprinting, to such an extent that we can make profoundly useful 3D tissue copies for fundamental and applied biomedicines.”

More information: Jinchang Zhu et al, All-aqueous printing of viscoelastic droplets in yield-stress fluids, Acta Biomaterialia (2022). DOI: 10.1016/j.actbio.2022.09.031

Journal information: Advanced Functional Materials , Acta Biomaterialia