Tissue repair, drug delivery, medical implants, and a wide range of other applications call for synthetic hydrogels. In bioelectronic devices for cardiac or neural interfaces, such as neural prosthetics, cardiac patches, and electronic skin, hydrogels with electrically conductive components can be utilized.

A new type of electroconductive hydrogel with outstanding mechanical strength and manufacturability has recently been developed by a team led by Dr. Lizhi Xu of the Department of Mechanical Engineering in the Faculty of Engineering at the University of Hong Kong (HKU). This opens up possibilities for the engineering of various bioelectronic devices.

In an article titled “Hybrid assembly of polymeric nanofiber networks for robust and electronically conductive hydrogels,” the new idea was published in Nature Communications.

“Presently available hydrogels are mechanically weak and difficult to manufacture, limiting their practical utility.” For the manufacture of conductive hydrogels, we developed a novel microscale scaffold. The composites’ architecture offers a mix of features unavailable to other hydrogels, which is critical for realistic applications in bioelectronic devices.”

Dr. Lizhi Xu of the Department of Mechanical Engineering in the Faculty of Engineering at the University of Hong Kong (HKU) .

Polymeric, water-rich synthetic hydrogels resemble biological soft tissues. They enable a physical interface between advanced biomedical tools and natural biological tissues because they are soft, porous, and biocompatible. Because they can be used in bioelectronic devices for cardiac or neural interfaces, electroconductive hydrogels have gotten a lot of attention from researchers.

“The existing hydrogels are unusable in practice because they are mechanically weak and difficult to manufacture. For the production of conductive hydrogels, we made use of a one-of-a-kind microscale scaffold. The design of the composites gave a blend of properties out of reach by different hydrogels, which is critical for practical applications in bioelectronic gadgets,” said Dr. Xu.

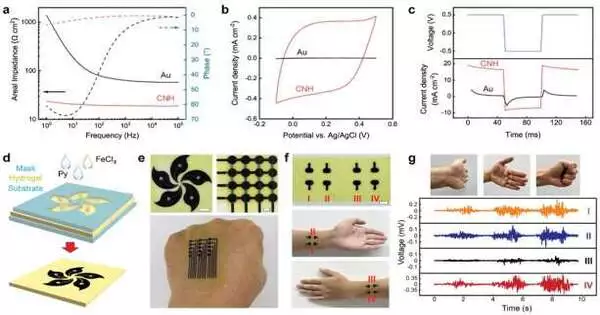

A 3D nanofiber network was used as a template to guide the assembly of conducting polymers (like polypyrrole) for the new hydrogels created by Dr. Xu’s team. The high network of the nanofibers gave both primary power and a compelling pathway for electron conduction.

“The device must be able to withstand the repeated mechanical loading caused by body motion for potential biomedical applications.” Dr. Xu elaborated, “In this regard, mechanical robustness of the materials would be very important.”

The subsequent material created by the group contains 80% water by weight while simultaneously showing a high electrical conductivity of 80 S/cm and a mechanical strength of 9.4 MPa.

“These conductive hydrogels are not difficult to manufacture.” Dr. Xu stated, “They can be patterned into arrays of electrodes, interconnects, and biosensors, enabling functional systems like cardiac tissue engineering platforms or wearable health monitors.”

He continued, “It opens opportunities for many advanced medical tools in the future, like neural prosthetics, cardiac patches, electronic skin, and so on.”

Another novel type of hydrogel that imitates tendons was previously developed by Dr. Xu and his research team. This hydrogel has remarkable mechanical properties that are very similar to those of natural tendons and a variety of functionalities that are ideal for biomedical applications.

More information: Huimin He et al, Hybrid assembly of polymeric nanofiber network for robust and electronically conductive hydrogels, Nature Communications (2023). DOI: 10.1038/s41467-023-36438-8