Two of humankind’s most omnipresent verifiable materials, concrete and carbon dark (which looks like extremely fine charcoal), may frame the reason for a novel, minimal expense energy capacity framework, as indicated by another review. By allowing energy networks to remain stable despite fluctuations in the supply of renewable energy, the technology has the potential to make it easier to make use of renewable energy sources like solar, wind, and tidal power.

The two materials, the scientists found, can be joined with water to make a supercapacitor — an option in contrast to batteries — that could give capacity of electrical energy.

For instance, the MIT scientists who fostered the framework say that their supercapacitor could ultimately be integrated into the substantial underpinning of a house, where it could store an entire day of energy while adding pretty much nothing (or no) to the expense of the establishment despite everything giving the required underlying strength. Additionally, the researchers envision a concrete road that could provide electric vehicles with contactless charging as they travel over it.

“The material is fascinating because it combines cement, the most commonly used man-made material in the world, with carbon black, a well-known historical material—the Dead Sea Scrolls were written with it. When you combine these at least two-millennia-old materials in a precise way, you get a conductive nanocomposite, and that’s where things get very fascinating.”

MIT professors Admir Masic,

The basic however creative innovation is portrayed in the diary PNAS, in a paper by MIT teachers Franz-Josef Ulm, Admir Masic, and Yang-Shao Horn, and four others at MIT and at the Wyss Establishment.

Capacitors are on a basic level exceptionally straightforward gadgets, comprising of two electrically conductive plates submerged in an electrolyte and isolated by a layer. Positively charged electrolyte ions build up on the negatively charged plate when a voltage is applied across the capacitor, while negatively charged ions build up on the positively charged plate.

Since the in the middle of between the plates blocks charged particles from relocating across, this partition of charges makes an electric field between the plates, and the capacitor becomes charged. The two plates can keep up with this sets of charges for quite a while and afterward convey them rapidly when required. Simply put, supercapacitors are capacitors that are capable of storing extremely large charges.

The total surface area of a capacitor’s conductive plates determines how much power it can store. A method for producing a cement-based material with an extremely high internal surface area due to a dense, interconnected network of conductive material within its bulk volume is the key to the new supercapacitors developed by this team.

The scientists accomplished this by presenting carbon dark — which is exceptionally conductive — into a substantial blend alongside concrete powder and water, and allowing it to fix. The water normally frames a spreading organization of openings inside the construction as it responds with concrete, and the carbon relocates into these spaces to make wire-like designs inside the solidified concrete. These designs have a fractal-like construction, with bigger branches growing more modest branches, and those growing significantly more modest branchlets, etc, winding up with an incredibly enormous surface region inside the limits of a somewhat little volume.

The material is then absorbed a standard electrolyte material, for example, potassium chloride, a sort of salt, which gives the charged particles that collect on the carbon structures. The researchers discovered that a very powerful supercapacitor is made up of two electrodes made of this material separated by a thin space or an insulating layer.

The two plates of the capacitor capability very much like the two shafts of a battery-powered battery of comparable voltage. When associated with a wellspring of power, likewise with a battery, energy gets put away in the plates, and afterward when associated with a heap, the electrical flow streams back on a mission to give power.

“The material is entrancing,” Masic says, “since you have the most-utilized synthetic material on the planet, concrete, that is joined with carbon dark, that is a notable verifiable material — the Dead Ocean Parchments were composed with it. You have these no less than two-centuries old materials that when you join them in a particular way you concoct a conductive nanocomposite, and that is when things get truly fascinating.”

As the combination sets and fixes, he says, “The water is efficiently drunk through concrete hydration responses, and this hydration in a general sense influences nanoparticles of carbon since they are hydrophobic (water repulsing).” As the combination develops, “the carbon dark is self-collecting into an associated conductive wire,” he says.

The cycle is effectively reproducible, with materials that are reasonable and promptly accessible anyplace on the planet. Furthermore, how much carbon required is tiny — just 3% by volume of the blend — to accomplish a permeated carbon organization, Masic says.

Supercapacitors made of this material can possibly help with the world’s change to sustainable power, Ulm says. Wind, solar, and tidal power are the main sources of emissions-free energy. Because they all produce at different times that frequently do not coincide with peak electricity consumption, ways to store that power are necessary.

“There is a huge need for a lot of energy storage,” he says. Existing batteries are too expensive and mostly rely on materials like lithium, which are hard to come by, so cheaper alternatives are crucial. Because cement is ubiquitous, that is where our technology is extremely promising,” states Ulm.

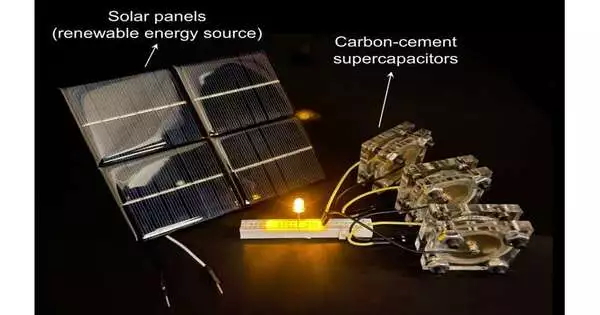

MIT engineers have made a “supercapacitor” made of old, bountiful materials, that can store a lot of energy. Made of simply concrete, water, and carbon dark (which looks like powdered charcoal), the gadget could frame the reason for economical frameworks that store discontinuously environmentally friendly power, for example, sun based or wind energy. Credit: Franz-Josef Ulm, Admir Masic, and Yang-Shao Horn

The group determined that a block of nanocarbon-dark doped substantial that is 45 cubic meters (or yards) in size — identical to a 3D shape around 3.5 meters across — would have sufficient ability to store around 10 kilowatt-long periods of energy, which is viewed as the normal day to day power utilization for a family.

A house with a concrete foundation could store a day’s worth of energy produced by windmills or solar panels and make it possible to use it whenever it was needed because the concrete would keep its strength. Furthermore, supercapacitors can be charged and released considerably more quickly than batteries.

The team demonstrated the process by making tiny supercapacitors that could each be charged to 1 volt, comparable to a 1-volt battery, after conducting a series of tests to determine the best ratios of cement, carbon black, and water. Each supercapacitor measured about one centimeter across and one millimeter thick. They then associated three of these to exhibit their capacity to illuminate a 3-volt light-radiating diode (Drove).

Having demonstrated the standard, they presently plan to fabricate a progression of bigger variants, beginning with ones about the size of a regular 12-volt vehicle battery, then, at that point, stirring up to a 45-cubic-meter rendition to show its capacity to store a house-worth of force.

There is a tradeoff between the capacity limit of the material and its primary strength, they found. Although the concrete is slightly weaker as a result of the addition of more carbon black, the resulting supercapacitor can store more energy. This could be useful in applications where the full strength-potential of concrete is not required.

They discovered that the “sweet spot” for applications like a foundation or structural elements of a wind turbine’s base is around 10% carbon black in the mix.

The construction of concrete roads with carbon-cement supercapacitors could also be used to store energy produced by solar panels along the road and then deliver that energy to electric vehicles traveling along the road using the same technology as wirelessly rechargeable phones. This is one potential application for carbon-cement supercapacitors. A connected kind of vehicle re-energizing framework is as of now being created by organizations in Germany and the Netherlands, yet involving standard batteries for capacity.

Introductory purposes of the innovation may be for disconnected homes or structures or safe houses a long way from lattice power, which could be controlled by sunlight based chargers connected to the concrete supercapacitors, the scientists say.

Ulm says that the framework is truly versatile, as the energy-stockpiling limit is an immediate capability of the volume of the terminals. ” You can go from 1-millimeter-thick terminals to 1-meter-thick cathodes, and thusly essentially you can scale the energy stockpiling limit from lighting a Drove for a couple of moments, to driving an entire house,” he says.

Contingent upon the properties wanted for a given application, the framework could be tuned by changing the blend. For a vehicle-charging street, extremely quick charging and releasing rates would be required, while for controlling a home “you have the entire day to energize it,” so more slow charging material could be utilized, Ulm says.

“In this way, it’s actually a multifunctional material,” he adds. The same kind of concrete mixture can be used as a heating system by simply applying electricity to the carbon-laced concrete, in addition to its capacity to store energy in the form of supercapacitors.

“A new way of looking toward the future of concrete as part of the energy transition” is Ulm’s description of this.

The examination group likewise included postdocs Nicolas Chanut and Damian Stefaniuk at MIT’s Branch of Common and Ecological Designing, James Weaver at the Wyss Establishment for Organically Propelled Designing, and Yunguang Zhu in MIT’s Division of Mechanical Designing. The Concrete Advancement Foundation provided sponsorship for the work, which received support from the MIT Concrete Sustainability Hub.

More information: Chanut, Nicolas, Carbon–cement supercapacitors as a scalable bulk energy storage solution, Proceedings of the National Academy of Sciences (2023). DOI: 10.1073/pnas.2304318120