As we look for more productive usage of waste nuclear power, the utilization of “stage change materials (PCMs)” is a decent choice. PCMs have a huge idle intensity limit and the capacity to store and deliver heat as they change, starting with one condition of issue and then onto the next. Among numerous PCMs, sugar alcohols (SAs), a class of natural mixtures generally utilized as sugars, stand out because of their minimal expense, non-harmful, non-destructive, and biodegradable nature.

Specifically, SAs, for the most part, have their dissolving point at 100–200 °C, which is a significant temperature range where an enormous measure of waste intensity exists yet is right now being disposed of in our reality.

In any case, SAs as a rule experience the ill effects of the issue of supercooling, where, rather than hardening, they stay in a fluid state even at temperatures well beneath the dissolving point. The supercooling corrupts the quality (or “exergy”) of put-away nuclear power since nuclear power at lower temperatures has less helpfulness. (Note: Nuclear power at room temperature is absolutely futile, regardless of its amount.)

“We propose a new materials concept that allows stored thermal energy to be retrieved at much higher temperatures than previously possible, largely by mitigating the long-standing issue of supercooling, which degrades the stored thermal energy.” We developed a new family of solid-state PCMs that are abundant, non-toxic, and inexpensive.”

Dr. Murakami, who is a Professor at the Laboratory for Zero-Carbon Energy at Tokyo Tech,

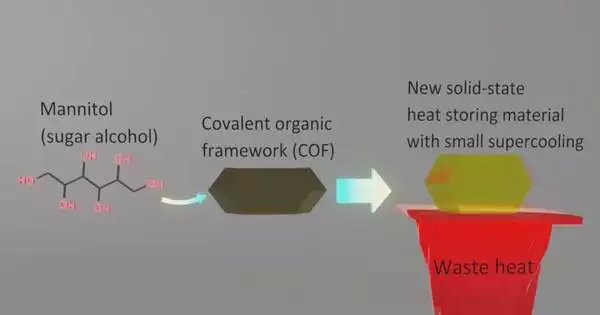

In another review, specialists from the Tokyo Establishment of Innovation (Tokyo Tech), led by Teacher Yoichi Murakami, found that restricting SAs in covalent natural structure (COF) gems really settles the issue of supercooling. Their discoveries, distributed in the Materials Skylines diary, can possibly change SAs as intensity-stockpiling materials.

Dr. Murakami, who is a teacher at the Research Center for Zero-Carbon Energy at Tokyo Tech, makes sense of, “We propose another material idea with which the put-away nuclear power can be recovered at a much higher temperature than previously, by generally moderating the well-established issue of supercooling that corrupts the put-away nuclear power. We have made another class of strong state PCMs in light of bountiful, non-harmful, and minimal expense SAs.”

Regularly, unadulterated D-mannitol (Man), one of the SAs, has a softening mark of 167 °C, yet it normally hardens indiscriminately at temperatures around 80–120 °C, which is a huge supercooling of around 47–87 °C. To determine this issue, the specialists brought man into the precious stones of COF-300, one of the most normal COFs. They found that while the dissolution of man restricted in the COF happened at around 150–155 °C, the freezing of man bound in the COF reproducibly happened in the marginally lower temperature range of 130–145 °C. In this manner, the supercooling has been stifled to just 10–20 °C, a lot more modest than the past supercooling of around 47–87 °C.

“These outcomes demonstrate that the combination freezing patterns of the Man-COF composite happen inside a tight temperature range of 130–155 °C without huge or irregular supercooling,” says Prof. Murakami, highlighting the impact of the COF restriction.

As per their distributed paper, prior works restricted SAs to unbending inorganic permeable materials, for example, nanoporous silica and alumina, to shape strong-state PCMs, yet they neglected to determine the supercooling issue of SAs. COFs are adaptable permeable materials as well as having a lot more modest pores (in the request for single-nanometer scale) than those of past inorganic nanoporous materials.

The current review is supposed to make ready for the new class of strong state heat capacity materials in light of green and minimal-cost SAs for effective nuclear power stockpiling.

More information: Yoichi Murakami et al, Composite formation of covalent organic framework crystals and sugar alcohols for exploring a new class of heat-storage materials, Materials Horizons (2023). DOI: 10.1039/D3MH00905J