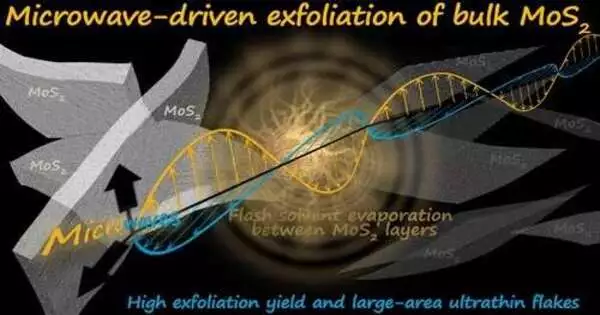

A new method for exfoliating MoS2 flakes that yields large, thin flakes has been developed by a group of researchers. The material quality is comparable to that of mechanical exfoliation, and the microwave-assisted exfoliation produces 50 times more flakes than ultrasonication. This quick process has the potential to open up new uses for electronic and photonic devices and requires little processing.

MoS2 is a transition metal dichalcogenide with a wide range of physical properties, ranging from semimetallic to semiconductor, superconductor, or insulator, depending on its dimensions. This makes it an intriguing material for use in electronics. These properties are determined by the number of stacked layers. For instance, bulk 2H-MoS2 has an indirect bandgap of 1.23 eV, while monolayer MoS2 has a direct bandgap of 1.90 eV. Because of their adaptability, these materials are ideal for use in various applications. However, it has been challenging to obtain large-area, high-quality MoS2 flakes.

It is challenging to obtain monolayer and few-layered 2H-MoS2 due to the low yields and broad thickness distributions produced by current liquid-phase exfoliation techniques. Researchers have looked into ball milling, electrochemical exfoliation, and fluid dynamics exfoliation in an effort to boost yields. However, these methods either produce metallic 1T- MoS2, which has distinct properties and applications, or they have issues with scalability.

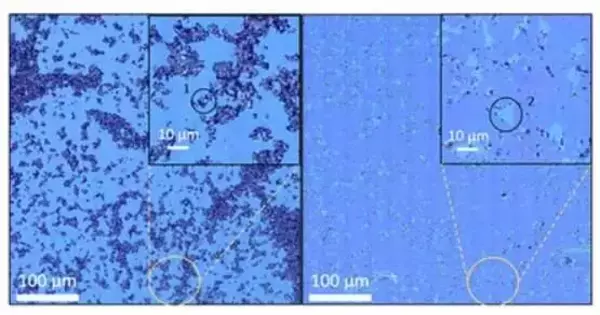

The MoS2 flakes highlighted in Figures 1 and 2 have a lateral dimension greater than 5 microns. Credit: A novel microwave-assisted method for exfoliating MoS2 flakes has been tested by a team led by Professors Victor Sebastián and Jess Santamara from the Institute of Nanoscience and Materials in Zaragoza (INMA, CSIC-UNIZAR) and Professor Emilio M. Pérez from the Madrid Institute of Advanced Studies in Nanoscience (IMDEA Nanociencia), both in Spain. They found that the strategy created all-around peeled material with parallel sizes tantamount to those acquired by mechanical shedding. The process yields approximately 50 times more than ultrasonication exfoliation techniques. It yields a material quality equivalent to mechanical peeling, whose chips are like those obtained by this technique, but with an especially better return (mechanical shedding is really done piece by piece). The procedure is simple and quick, taking only a few minutes to complete.

“2D materials in general, and transition-metal dichalcogenides in particular, are promising for a variety of technologies (sensors, electronics, etc.), but it all starts with producing high-quality materials in big quantities and at a low cost. This is where our work can help. It is not a step toward a new technical technology, but rather a tool to aid in the realization of all of the hope put on 2D materials.”

Professors Sebastián and Pérez

Each case’s thickness, lateral size, yield, and processing time are improved by this method, which combines the best aspects of mechanical and liquid-phase exfoliation. A microwave-assisted, high-yield, fast method that yields well-exfoliated, few-layered MoS2 flakes marks the researchers’ approach as a significant advance in the field of MoS2 exfoliation. MoS2 could be used in new ways in electronic and photonic devices with this method. It has been used to exfoliate MoS2, but it could also be used to exfoliate any material with a high microwave absorption capacity. This makes it a versatile strategy for new 2-dimensional (2-D) materials. The scientists intend to examine the strategy further, investigating its versatility and likely applications in more detail.

The most exciting aspect of your findings, according to Professors Sebastián and Pérez, is “the lateral size of the flakes.” Naturally, exfoliation methods require 2D materials to be extremely thin, but it is frequently overlooked that lateral size is also important for most applications. However, all exfoliation techniques involve adding some form of energy to the bulk material in order to overcome the van der Waals interactions between layers, making it difficult to produce flakes that are both large and thin at the same time while also yielding a high quantity. Additionally, preventing the same energy from simultaneously causing lateral damage is difficult. Using microwaves, we are able to quickly create a high pressure between the layers, allowing them to be separated without being damaged by our method.”

The researchers respond, “2D materials in general, and transition-metal dichalcogenides in particular, are promising for a lot of technologies (sensors, electronics, etc.)” when asked about the method’s potential applications in real life. But obviously, the first step is to produce these materials at a low cost and, ideally, in large quantitiespromising for a lot of technologies (sensors, electronics, etc.)” when asked about the method’s potential applications in real life. But obviously, the first step is to produce these materials at a low cost and, ideally, in large quantities. Our work can help in this area. It is not a step toward a new technology; rather, it is a tool that will help all of the hope that has been placed in two-dimensional materials become a reality.”

The study has been published in the ACS Nano journal.

More information: Ramiro Quirós-Ovies et al, Microwave-Driven Exfoliation of Bulk 2H-MoS2 after Acetonitrile Prewetting Produces Large-Area Ultrathin Flakes with Exceptionally High Yield, ACS Nano (2023). DOI: 10.1021/acsnano.3c00280