Helium particle pillar (HIB) innovation assumes a significant part in the outrageous fields of nanofabrication. Because of high goals and awareness, HIB nanofabrication innovation is broadly used to design nanostructures into parts, gadgets, or frameworks in coordinated circuits, materials sciences, nano-optics, and biological sciences applications. HIB-based nanofabrication incorporates direct-compose processing, particle pillar actuated testimony, and direct-compose lithography without the need for opposing help. Their nanoscale applications have additionally been assessed in the space of coordinated circuits, materials sciences, nano-optics, and organic sciences.

In another paper distributed in the International Journal of Extreme Manufacturing, a group of specialists, led by Dr. Deqiang Wang from the Chongqing Key Laboratory of Multi-scale Manufacturing Technology, Chongqing Institute of Green and Intelligent Technology, Chinese Academy of Sciences, PR China, have summed up extensively the outrageous cycles and utilizations of HIB nanofabrication.

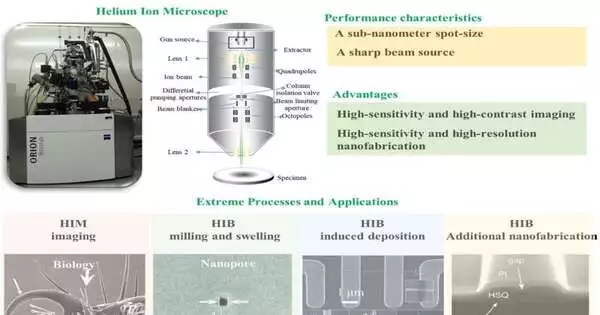

The primary point of this audit is to address the most recent improvements in HIB innovation with their outrageous handling capacities and broad applications in nanofabrication. In view of the presentation of the HIM framework with GFIS, the exhibition attributes and benefits of HIB innovation have been examined first. From there on, certain inquiries concerning the outrageous cycles and utilizations of HIB nanofabrication have been tended to: what number of outrageous cycles and uses of HIB innovation have been created in nanofabrication for coordinated circuits, materials sciences, nano-optics, and biological science applications? What are the fundamental difficulties in outrageous nanofabrication with HIB innovation for high-goal and awareness applications?

“By HIB milling on a thin silicon nitride membrane or suspended graphene, nanometer-scale nanopores that are useful for single base recognition of DNA/RNA sequences can be created for extreme nanofabrication. Specific 3D nanopores are encouraged to form by amorphization during the milling process, which has the potential to be used in bioscience and nano-optics.”

Professor Deqiang Wang (Director of Chongqing Key Laboratory of Multi-scale Manufacturing Technology, CIGIT)

HIM enjoys the benefits of high goals and responsiveness for outrageous nanostructure creations. HIB-based nanofabrication incorporates direct-compose processing, particle pillar instigated testimony, and direct-compose lithography without the need for opposing help. Their nanoscale applications have additionally been assessed in the space of coordinated circuits, materials sciences, nano-optics, and natural sciences. This survey basically covers four topical utilizations of HIB: 4) Additional HIB direct composition for opposing, graphene, and plasmonic nanostructures.

HIB innovation is utilized for high-contrast, high-goal imaging of conductive, semiconductor, protecting materials, and natural examples. Although the particles crash into the objective example, it will be preferable over customary SEM imaging. The engaged HIB innovation has particular advantages in nanofabrication, such as near thickness control processing and nanostructures manufacturing in unattached layers or mass materials.Nonetheless, the amorphization and helium implantation might cause test harm during HIB processing on mass substrates. As a result, advancement of particle portion, bar energy, and HIB portion rate is critical for near thickness control and geographic exactness control in nanostructures production.Particle pillar initiated testimony is a significant nanofabrication innovation, which can alter the properties of materials as indicated by the cooperation between the particle shaft and materials. The improvement of HIB-initiated testimony is a sensible and fitting procedure for these specific nanofabrication applications due to the light mass of helium particles and the different electrical properties between inactive helium and electroactive gallium. Because of the sub-nanometer spot size, the engaged HIB is utilized as a new, high-goal direct composing openness bar for nanofabrication. HIB direct writing is equivalent to or better than electron shaft lithography for nanoelectronic gadget manufacture due to its high goal, high SE yield, and low vicinity impact.Furthermore, because of their moderately low mass, helium particles cause less damage to uncovered target substrates than other particles such as electrons and gallium particles.

Teacher Deqiang Wang (Director of Chongqing Key Laboratory of Multi-scale Manufacturing Technology, CIGIT), Professor Wen-Di Li, Professor Wei Wu, Dr. Shixuan He, and Dr. Rong Tian have recognized a couple of basic difficulties in the outrageous cycles and uses of HIB nanofabrication as follows:

“For outrageous nanofabrication, nanometer-scale nanopores that are helpful for single base acknowledgment of DNA/RNA groupings can be manufactured by HIB processing on diminished silicon nitride film or suspended graphene.” Amorphization during the processing system advances the development of explicit 3D nanopores, which can be utilized for potential nano-optics and bioscience applications. “

“The synthetic response of the forerunner gas particles adsorbed on a superficial level prompted by HIB brings about the immediate statement of modified 3D designs at the nanoscale.”

“HIB direct composition without opposing help is utilized to design sub-10-nm nanochannels, nanoribbons, and nanostructures for nanoscale useful gadgets.”

Both HIM imaging and HIB nanofabrication should consider the inescapable harm which is brought about by the crash between helium particles and the test substrate. HIB innovation has a lower faltering yield, but can create more harm on the substrate in nanofabrication handling, like air pockets, implantation, and amorphization. “More top-to-bottom speculative research on the connection instrument between helium particles and materials has advanced the improvement of the handling ability of the extraordinary nanofabrication with HIB innovation.”

The steadiness and repeatability of the HIB processing cycle will be upgraded to meet the prerequisites of sub-nanometer goals and high-throughput creation in extraordinary applications. While improving the nanofabrication interaction, the positive or adverse consequence of helium particles’ barrage on the material properties ought to be thought of, so HIB innovation can be utilized to straightforwardly manufacture nanostructures with fewer imperfections and fantastic execution. “

“For direct-compose HIB strategy and HIB-actuated statement processes, the normal test is to build the intricacy of nanostructures while keeping up with the nanoscale, including size for the extraordinary applications.” To expand the intricacy of nanostructures and their applications underway, the immediate creative cycle of HIB innovation should be worked on through cautious streamlining of boundaries. Additionally, the closeness impact ought to be likewise thought about in the HIB direct composition and HIB-actuated affidavit processes. “

Scientists have shown that HIB innovation will assume a significant part in outrageous nanofabrication since it enjoys the benefits of high responsiveness, goal, and accuracy for direct composing processing, designing, helped processing, and statement processes with less harms to the examples.

More information: Shixuan He et al, Helium-ion-beam nanofabrication: extreme processes and applications, International Journal of Extreme Manufacturing (2020). DOI: 10.1088/2631-7990/abc673