Have you ever longed to have a gingerbread house like Hansel and Gretel?

Sooner rather than later, eatable houses will not just be found in fantasies.

Tokyo University specialists Kota Machida and Yuya Sakai have fostered an innovation to change food squander into possibly eatable “concrete” for development use.

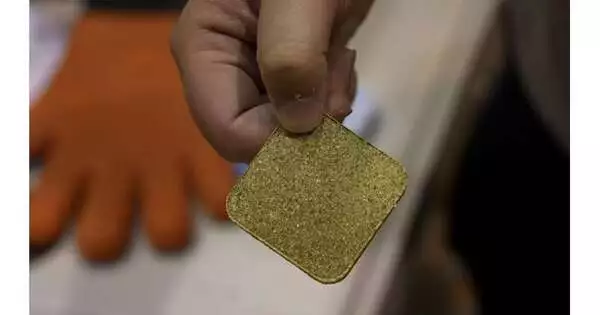

It’s the world’s most memorable interaction for making concrete completely from food squander. The analysts say the elastic, or bowing, strength of their item is almost fourfold that of conventional cement.

“Our ultimate hope is that this cement replaces plastic and cement products, which have worse environmental impacts,”

Kota Machida

Machida and Sakai say they desire to assist with reducing an Earth-wide temperature boost by reducing issues connected with squandered food materials that radiate methane when they decay while covered in landfills.

Sakai, an academic partner of Industrial Science, fostered the innovation while exploring maintainable materials that could supplant concrete-based concrete. As indicated by the research organization Chatham House, concrete production accounts for 8% of the world’s carbon dioxide discharges.

He initially fostered a method for making concrete by exposing pummeled wood particles to warm pressure. The three-venture cycle of drying, crushing, and pressure was finished utilizing straightforward blenders and blowers, which the scientists say can be purchased on Amazon.

Tokyo University analysts Yuya Sakai, right, and Kota Machida present items they made from “food concrete” at their research facility in Tokyo on May 26, 2022. Sakai and Machida fostered an innovation that can change food squander into “concrete” for development use. Photographer: AP/Chisato Tanaka

Sakai, with his understudy Machida, concluded to do exactly the same thing with food waste. Past preliminary utilizing food waste to make concrete, expect plastics to be blended in to get the materials to stay together.

After quite a while of disappointment, they understood they could get the concrete to tie by changing the temperature and tension utilized.

“The most difficult aspect was that each sort of food waste requires various temperatures and tension levels,” Sakai said.

Various tests in utilizing food waste in development have primarily focused on utilizing stuff, such as espresso beans or bio-squander remaining as filler in standard cement.

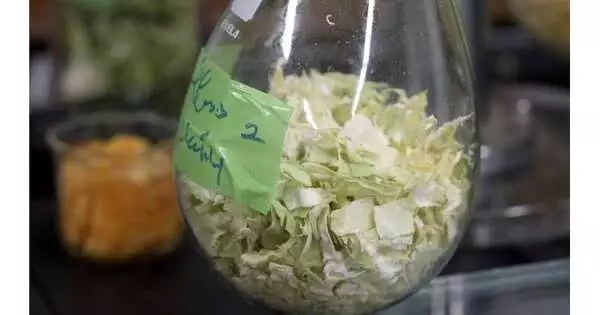

Sakai and Machida say they have effectively made concrete utilizing tea leaves, orange and onion strips, coffee beans, Chinese cabbage, and even lunchbox extras.

They’ve changed flavors with various flavors and found the variety, fragrance, and taste of the concrete very appealing. To have the option to eat the material, an individual would have to break it into pieces and bubble it, Sakai said.

To make the concrete waterproof and shield it from being eaten by rodents and other nuisances, it may very well be covered with Japanese veneer.

Food waste is an enormous issue in Japan and around the world. Japan created around 5.7 million tons of eatable food squander in 2019 and the public authorities intend to decrease that to around 2.7 million tons by 2030.

Machida began an organization called Fabula Inc. last year with two of his lifelong companions. They are working with different organizations to make cups, cutlery, and furniture out of food-grade concrete.

Sakai says the interaction could be utilized to make eatable stopgap lodging for catastrophes.

He said that, on the off chance that food can’t be conveyed to evacuees, they could eat shoddy beds made from food concrete.

The food concrete can be reused and is biodegradable, so it tends to be covered when it is not generally required.

“Our definitive expectation is that this concrete will replace plastic and concrete items, which have more awful natural effects,” said Machida.