Organic product flies can rapidly make up for horrendous wing wounds, scientists found, keeping up with a similar level of security after losing up to 40% of a wing. This finding could inform the plan regarding flexible robots, which face the comparative test of having to adjust to disasters in the field rapidly.

The Penn State-driven group distributed their outcomes today in Science Advances.

To run the investigation, scientists modified the wing length of anesthetized natural product flies, copying a physical issue flying bugs can maintain. They then, at that point, suspended the flies in a computer-generated simulation ring. Emulating what flies would see when in flight, scientists played virtual symbolism on minuscule screens in the ring, making the flies move as though they were in flight.

“We found flies make up for their wounds by fluttering the injured wing harder and lessening the speed of the sound one,” said relating creator Jean-Michel Mongeau, a Penn State associate teacher of mechanical design. “They achieve this by balancing signals in their sensory system, permitting them to adjust their flight even after a physical issue.”

“We discovered that flies adjust for injuries by flapping the damaged wing harder and slowing down the healthy one. They do this by altering neural system signals, letting them to fine-tune their flying even after an injury.”

Jean-Michel Mongeau, Penn State assistant professor of mechanical engineering.

Organic product flies trade some exhibition (which marginally reduces soundness) for keeping up with soundness by effectively expanding damping by fluttering their harmed wing harder.

“In the event that you drive on a cleared street, erosion is kept at bay between the tires and the surface, and the vehicle is steady,” Mongeau said, contrasting damping with grinding. “Be that as it may, on a cold street, there is diminished erosion between the street and tires, causing flimsiness. For this situation, an organic product fly, as the driver, effectively increments damping with its sensory system trying to increment soundness.

Co-creator Bo Cheng, Penn State Kenneth K., as well as Olivia J. Kuo, an early-vocation academic partner of mechanical design, noticed that steadiness was a higher priority than power for flight execution.

“Under wing harm, both execution and strength would regularly endure; nonetheless, flies utilize an “inside handle” that builds damping to keep up with the ideal soundness, regardless of whether that prompts further declines in execution,” Cheng said. “Truth be told, it has been shown that it is without a doubt the strength, rather than the necessary power, that limits mobility in flies.”

The specialists’ work recommends that organic product flies, with only 200,000 neurons compared with 100 billion in people, utilize a complex, adaptable engine control framework, permitting them to adjust and make due after a physical issue.

“The intricacy we’ve revealed here in flies is unrivaled by any current design framework; the refinement of the fly is more mind-boggling than existing flying robots,” Mongeau said. “We are still far away on the designing side of attempting to imitate what we find in nature, and this is simply one more illustration of exactly how far we need to go.”

With progressively complex conditions, engineers are tested to plan robots that can adjust rapidly to deficiencies or accidents.

“Flying bugs can rouse the idea of fluttering robots and robots that can respond brilliantly to actual harm and keep up with activities,” said co-creator Wael Salem, a Penn State doctoral applicant in mechanical design. “For example, planning a robot that can compensate for a faulty engine in flight or a legged robot that can rely on its different legs when one fails.”

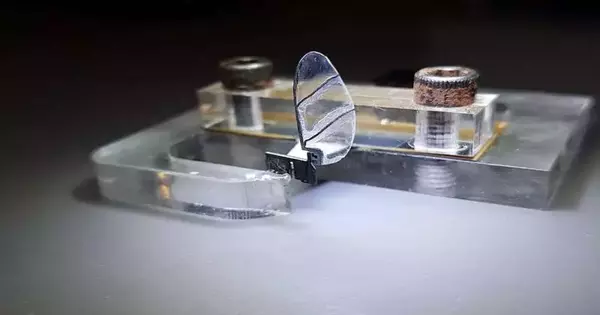

To focus on the component by which flies compensate for wing damage in flight, colleagues at the University of Colorado Stone created a robot model of a mechanical wing that was similar in size and capability to that of an organic product fly.Scientists cut the mechanical wing, reproducing the Penn State experiments, and tried the cooperation between the wings and the air.

“With just a numerical model, we want to improve on assumptions about wing design, wing movement, and wing-air cooperations to make our calculations manageable,” said co-creator Kaushik Jayaram, right-hand mechanical design professor at the College of Colorado.”Yet, with an actual model, our robot model collaborates with the regular world similar to how a fly would, dependent upon the laws of material science.” As a result, this arrangement captures the complexities of the complex wing-air associations that we don’t yet fully comprehend.

Notwithstanding Mongeau, Cheng, Salem, and Jayaram, the co-creators include Benjamin Cellini, Penn State Branch of Mechanical Designing; and Heiko Kabutz and Hari Krishna Hari Prasad, College of Colorado Rock.

More information: Wael Salem et al, Flies trade off stability and performance via adaptive compensation to wing damage, Science Advances (2022). DOI: 10.1126/sciadv.abo0719. www.science.org/doi/10.1126/sciadv.abo0719

Journal information: Science Advances