Engineers from the University of Illinois Chicago are part of a collaborative team that has created a material that could provide fuel cell systems a competitive advantage over battery systems, which presently power the majority of electric vehicles.

Unlike lithium batteries, fuel cell technology creates energy through catalyst-driven chemical reactions. Lithium batteries can often travel 100-300 miles on a single charge, but they are also subject to costly cathode material and production costs, and charging takes several hours.

Fuel cell systems, on the other hand, employ abundant components such as oxygen and hydrogen to go over 400 miles on a single charge, which takes approximately five minutes. Unfortunately, the catalysts they use to drive their reactions are either too expensive (such as platinum) or decay too quickly to be practical.

We learnt what was going on in the atomic structure of additives through our structural analyses, and we were able to identify the size and dimensions of the scavenger nanoparticles, as well as the ratio of tantalum and titanium oxide.

Shahbazian-Yassar

In contrast to lithium batteries, fuel cell technology generates energy through catalyst-driven chemical processes. Lithium batteries can normally travel 100-300 miles on a single charge, but they are subject to the high cost of cathode materials and manufacture, and they take several hours to charge. Alternatively, fuel cell systems take advantage of abundant elements such as oxygen and hydrogen and can achieve more than 400 miles on a single charge — which can be done in under five minutes. Unfortunately, the catalysts used to power their reactions are made of materials that are either too expensive (i.e., platinum) or too quickly degraded to be practical.

That is, until now. Scientists can make an affordable iron-nitrogen-carbon fuel cell catalyst more durable by developing a new additive material. When added to chemical operations, the additive material shields fuel cell systems from two of the most corrosive byproducts: free radicals, which are unstable particles like atoms, molecules, or ions, and hydrogen peroxide.

Findings from their experiments are reported in the science journal Nature Energy.

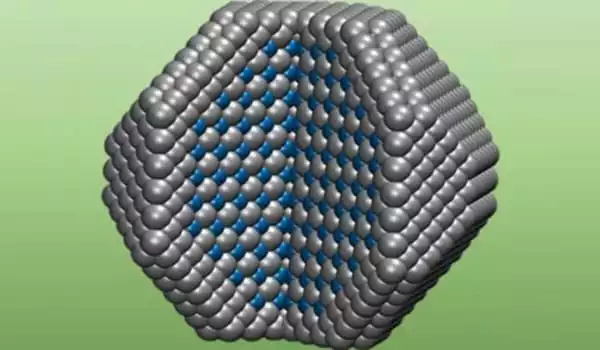

Reza Shahbazian-Yassar, professor of mechanical and industrial engineering at the University of Illinois at Chicago, and colleagues investigated the reactions with the substance, a tantalum-titanium oxide nanoparticle additive that scavenges and deactivates free radicals. The scientists were able to identify the structural characteristics required for the additive to operate thanks to high-resolution photography of the atomic structures.

“We can employ electron microscopy in our lab to collect highly detailed, atomic-resolution images of the materials under a variety of service situations,” stated study co-corresponding author Shahbazian-Yassar. “We learnt what was going on in the atomic structure of additives through our structural analyses, and we were able to identify the size and dimensions of the scavenger nanoparticles, as well as the ratio of tantalum and titanium oxide. This resulted in a better understanding of the proper state of the solid solution alloy required for the additive to protect the fuel cell from corrosion and deterioration.”

Experiments revealed that a solid solution of tantalum and titanium oxide is required and that the nanoparticles should be around five nanometers. The experiments also revealed that a 6-4 ratio of tantalum to titanium oxide is required.

“The ratio is the key to the radical scavenging properties of the nanoparticle material and the solid-state solution helped sustain the structure of the environment,” Shahbazian-Yassar said.

The investigations revealed that when the scavenger nanoparticle material was added to the reactions of fuel cell systems, hydrogen peroxide output was suppressed to less than 2% – a 51% reduction – and fuel cell current density decay was lowered from 33% to 3%.

According to the researchers, the novel catalyst outperforms the US Department of Energy (DOE) targets for both initial activity and long-term durability, with an initial activity of 0.56 amps per milligram and an activity after 30,000 cycles (approximately five years within a fuel cell) of 0.45 amps.

“Fuel cells are an appealing alternative to batteries because of their higher driving range, fast recharging capabilities, less weight, and smaller volume, assuming we can find more cost-effective ways to extract and store hydrogen,” Shahbazian-Yassar explained. “In this work, we report on a strategy that brings us considerably closer to realizing fuel cell-powered vehicles and other fuel cell technologies.”