Researchers have developed a method for increasing the flexibility of ultra-thin electronics, such as those used in bendable devices or clothing. They achieved this by using water-vapor plasma to directly bond gold electrodes fixed to separate ultra-thin polymer films. This is a significant step forward because the technique does not require adhesives or high temperatures.

Researchers at Japan’s RIKEN Center for Emergent Matter Science (CEMS) and the RIKEN Cluster for Pioneering Research (CPR) have developed a technique to improve the flexibility of ultra-thin electronics used in bendable devices or clothing. The study, which was published in Science Advances, describes how water vapor plasma was used to directly bond gold electrodes fixed onto separate ultra-thin polymer films without the use of adhesives or high temperatures.

As electronic devices become smaller and smaller, and as the desire for bendable, wearable, and on-skin electronics grows, traditional methods of building these devices become impractical. One of the most difficult issues is figuring out how to connect and integrate multiple devices or pieces of a device that are all housed on separate ultra-thin polymer films. Conventional methods of adhering electrodes together that use layers of adhesive reduce flexibility and necessitate temperatures and pressures that are harmful to super-thin electronics. Traditional methods of direct metal-to-metal bonding are available, but they necessitate perfectly smooth and clean surfaces, which are not common in these types of electronics.

This is the first demonstration of ultra-thin, flexible gold electronics fabricated without the use of adhesive. We were able to fabricate an integrated system of flexible organic solar cells and organic LEDs using this new direct bond technology.

Kenjiro Fukuda

A team of researchers at RIKEN CEMS/CPR led by Takao Someya developed a new method to secure these connections that do not require adhesive, high temperature, or high pressure and do not require completely smooth or clean surfaces. In fact, at room temperature, the process takes less than a minute, followed by a 12-hour wait. The new technique, known as water-vapor plasma-assisted bonding, uses a thermal evaporator to create stable bonds between gold electrodes printed into ultra-thin – 2 thousandths of a millimeter! – polymer sheets.

“This is the first demonstration of ultra-thin, flexible gold electronics fabricated without the use of adhesive,” says RIKEN CEMS/CPR Senior Research Scientist Kenjiro Fukuda. “We were able to fabricate an integrated system of flexible organic solar cells and organic LEDs using this new direct bond technology.”

Experiments revealed that water-vapor plasma-assisted bonding outperformed traditional adhesive and direct bonding techniques. The strength and consistency of the bonds, in particular, were greater than that of standard surface-assisted direct bonding. At the same time, the material conformed better to curved surfaces and was more durable than a standard adhesive technique could achieve.

According to Fukuda, the method is surprisingly simple, which may explain why they discovered it by chance. Following the attachment of the gold electrodes to the polymer sheets, a machine is used to expose the electrode sides of the sheets to water-vapor plasma for 40 seconds. The polymer sheets are then pressed together so that the electrodes overlap in the proper place. They are ready to use after 12 hours in room temperature. Another advantage of this system is that the films can be stored in vacuum packs for days after activation with water-vapor plasma but before being bonded together. When considering the possibility of ordering and distributing pre-activated components, this is an important practical consideration.

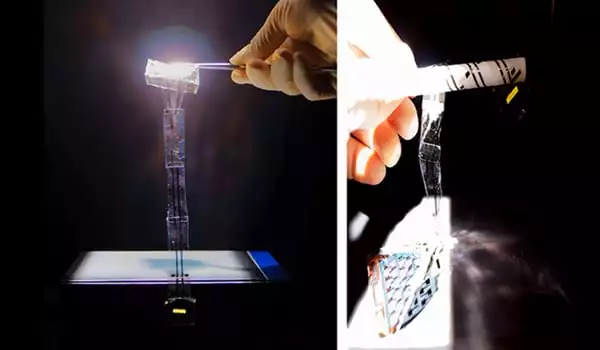

The team demonstrated the concept by integrating ultra-thin organic photovoltaic and LED-light modules printed on separate films and connected by five additional polymer films. The devices were put through rigorous testing, including being wrapped around a stick and crumpled and twisted to extremes. Furthermore, the treatment had no effect on the power efficiency of the LEDs. The method could also connect pre-packaged LED chips to a flexible surface.

“We anticipate that this new method will become a flexible wiring and mounting technology for next-generation wearable electronics that can be attached to clothing and skin,” Fukuda says. “The next step is to adapt this technology for use with less expensive metals like copper or aluminum.”