Protection of the great strain conditions of materials under surrounding conditions is a long-sought-after objective for key exploration and viable applications.

A group of researchers led by Drs. Zhidan (Denise) Zeng, Qiaoshi Zeng, and Ho-Kwang Mao from the Center for High Pressure Science and Technology Advanced Research (HPSTAR) and Prof. Wendy Mao from Stanford University report a creative advancement where they had the option to keep up with the uncommon properties of high-pressure materials in detached, nanostructured jewel cases without the help of customary massive strain vessels. Their work has as of late been distributed in Nature.

Current innovation is based upon admittance to materials with reasonable physical and chemical properties that can be utilized to carry out unambiguous roles in different gadgets. Innovative advances, hence, are many times directed by the improvement of unrivaled materials with helpful properties. Everything being equal, high strain can radically change or tune properties, everything being equal to finding novel materials with very good properties.

The proviso is, nonetheless, that the good properties frequently and possibly exist under tension when the example stays in the massive high-pressure vessel, restricting logical examination and likely applications. For as long as a century, researchers have attempted to beat this problem. They succeeded exclusively in “quenchable” stages, where novel materials blended at high strain hold their good properties subsequent to delivering pressure. A notable example is the high-pressure transformation of ordinary carbon into a jewel, which can retain its radiance and other exceptional properties after recovering at normal tensions.

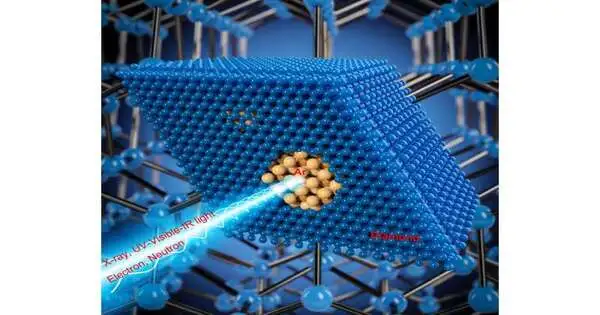

“By using high-resolution transmission electron microscopy, we directly see several nanometer-sized high-pressure argon grains contained in the nano-diamond matrix; consequently, we dubbed them nanostructured diamond capsules (NDCs).”

Dr. Denise Zhidan Zeng, the lead author of this work.

Sadly, such fruitful instances of quenchable stages are very uncommon, generally delivering high-pressure materials investigations of just scholarly premium with minimal viable worth in the surrounding climate.

The HPSTAR and Stanford research groups fostered a clever methodology that has shown the capacity to extinguish even shaky gases and save their high-pressure properties. They compressed shiny carbon, a nebulous type of permeable carbon, with argon gas to 50 gigapascals (multiple times air pressure) and heated the example to 3,320 degrees Fahrenheit.

The shiny carbon that is at first impermeable to gases under normal circumstances retains argon like a wipe at high tensions. The use of high strain and temperature conditions changes the carbon into a jewel and traps the now strong, high-pressure argon in its pores. The subsequent example that is recovered at surrounding conditions acts like a nanocrystalline jewel composite with various confined pores that act like small precious stone cases loaded up with argon.

The leftover strain saved in the argon by the jewel case is basically as high as 22 gigapascals—multiple times the tension at the lower part of the Mariana Trench. Even better, the compressed argon test is fixed in by just nanometer-thick jewel skins, permitting its uncommon properties to be tested by current logical tests that expect close to vacuum conditions like electron microscopy.

“By high-goal transmission electron microscopy, we directly notice numerous nanometer-sized high-pressure argon grains typified in the nano-jewel grid; thus, we named them nanostructured precious stone cases (NDCs),” explained Dr. Denise Zhidan Zeng, the lead creator of this work.

One of the keys to understanding the idea of NDCs is picking the right carbon forerunner, which is sp2 fortified and has prior encased example chambers. This is clearly in no way, shape, or form restricted to shiny carbon. Hence, an assortment of glasslike, nebulous, and low-layered carbon allotropes might actually be utilized as the forerunner carbon too, offering an extensive variety of case materials for improvement of the NDC cycle, “made sense of Zeng.”

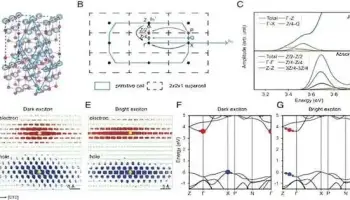

“Utilizing various integral analytic tests to get steady outcomes includes the advanced matter examination.” Nonetheless, in-situ high-pressure examinations have consistently required high-entry tests, for example, hard X-beam, because of the thick high-pressure vessel walls included. Hence, numerous strong and flexible tests, for example, electron microscopy and vacuum bright to delicate X-beam spectroscopy, that require a close to vacuum climate, sadly, stay contrary to high-pressure science and innovation. “This has seriously upset our endeavors to grasp some high-pressure materials,” said Dr. Qiaoshi Zeng.

By blending NDCs, we offer an overall strategy to eliminate massive strain vessels while keeping up with the high-pressure conditions and hence the high-pressure conduct in our examples. We can now utilize practically every one of the advanced analytic tests to get definite data about the nuclear/electronic designs, pieces, and holding nature of materials at high tensions inside NDCs, including different methods in view of transmission electron microscopy. We are amped up for the likelihood that a methodology in view of NDCs will welcome high-pressure investigations comparable to regular dense matter examinations and applications. “

“Past the gases that we investigated in our review, we likewise anticipate that the idea of NDCs should be by and large relevant to different strong examples,” said Prof. Wendy Mao.

Besides, NDC tests are on a basic level with the potential for limitless, various unions, hence eliminating the limit where high-pressure peculiarities just exist in a small example inside a huge strain chamber. Hence, our work shows the first, basic move toward the great test of high-pressure materials applications for already ravenous stages. “

More information: Wendy Mao, Preservation of high-pressure volatiles in nanostructured diamond capsules, Nature (2022). DOI: 10.1038/s41586-022-04955-z. www.nature.com/articles/s41586-022-04955-z

Journal information: Nature