Water electrolysis is a viable strategy for creating hydrogen utilizing sustainable wellsprings of energy. The improvement of savvy electrocatalysts for effective and solid hydrogen advancement response in basic media is of crucial significance to satisfy the rising need for hydrogen.

The platinum group metals exhibit excellent activity in hydrogen advancement response, but their high cost limits their widespread application.

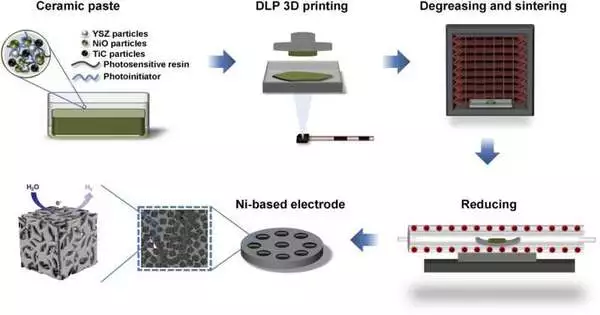

As of late, an exploration group led by Prof. Tang Zhiyong and Associate Professor Zhang Jie from the Shanghai Advanced Research Institute (SARI) of the Chinese Academy of Sciences has proposed a clever photo-restoring 3D-printing strategy to straightforwardly make organized nickel-based electrocatalysts with novel gluten-like cubic design areas of strength for and substrate connection.

The review was published in Nano Energy.

Photograph restoration 3D printing has a much lower production cost than specific laser softening 3D printing and a much higher level of capability and printing precision than direct ink composition 3D printing.

In view of this innovation, the analysts upgraded the printing glue piece and post-treatment process. The resultant anode surface shows a gluten-like cubic design, where Ti exists in nebulous state areas of strength with Ni, prompting expanded dynamic locales and worked on electrolytic properties.

The customized nickel-based terminal shows great strength and a strikingly low overpotential, outperforming the business Pt/C impetus and the majority of the cutting-edge electrocatalysts.

The useful hypothesis estimations further uncover that the Ti doping diminishes water separation energy boundary and hydrogen energy hindrance, hence upgrading the hydrogen advancement response.

This work gives a clever system to exactly set up the honorable sans metal impetuses with improved action in basic water electrolysis. Also, the created photo-reparable 3D printing strategy gives an elective choice to assemble minimal-cost electrocatalysts with complex 3D design.

More information: Zhaojing Han et al, Direct photo-curing 3D printing of nickel-based electrocatalysts for highly-efficient hydrogen evolution, Nano Energy (2022). DOI: 10.1016/j.nanoen.2022.107615