Holographic interferometry is the method of estimating pressure, strain, and vibration with light. It is characterized by the frequency of light, tracking down blemishes in primary bonds. It takes full advantage of a 3D image’s capacity to duplicate the optical field reflected or sent by an item.

Holographic interferometry uses two unexpected capacities of visualization. Initial, a visualization can record garbled fields and reproduce them lucidly with the goal of letting them meddle in their recreated fields. Furthermore, a multi-dimensional image can recreate the optical field of an item. It tends to be revamped with such loyalty that it obstructs the first field of the article when migrated from its unique position.

In a survey paper distributed in Light: Advanced Manufacturing, Karl Stetson of Karl Stetson Associates has related the revelation of holographic interferometry, examined its turn of events, and organized a portion of its significant applications. The paper, “The revelation of holographic interferometry: its turn of events and applications,” surveyed the first tests and what could occur from here on out.

The creator was roused by “Holographic Visions: A History of New Science” by Sean Johnston, yet felt a significant feeling of disappointment. So he attempted to reconsider the way to deal with a considerable number of the tests depicted in the book. It permitted him to assess all that with an open-minded perspective and test the hypotheses.

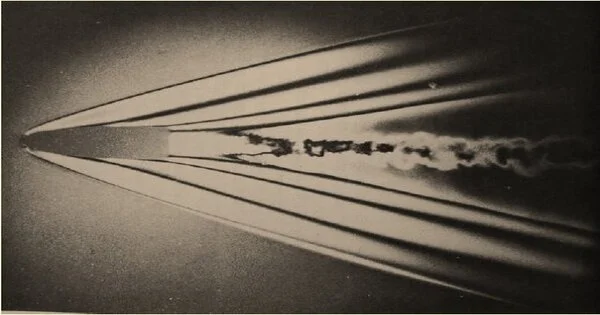

Unintentionally, the laser shot a two-fold heartbeat. The first happened before the slug was in the field of view.

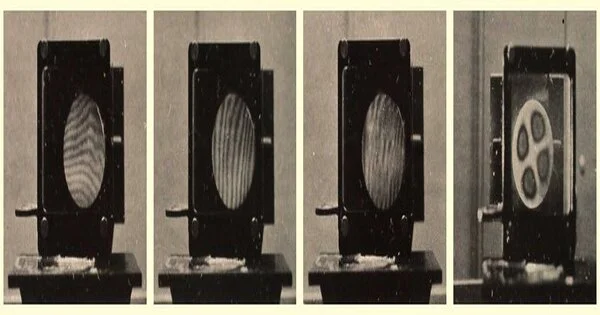

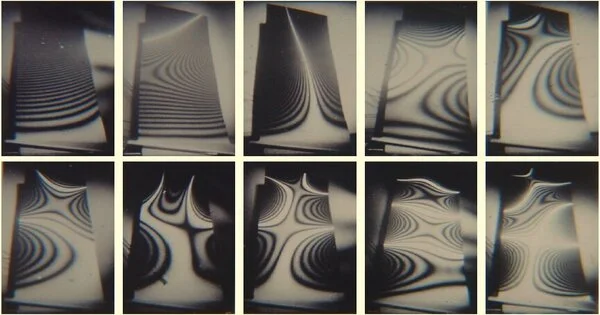

One model was the obstruction borders on the edges of explicit holographic reproductions. The creator made sense of how his group cooperated to change their technique, contrasting with numerous a very long time previously. They observed that it was fundamental to survey appropriately the way in which these edges happened. Through their trial and error, the group observed that it was most useful in estimating constant vibration on intelligent surfaces.

Estimating continuous vibrations on intelligent surfaces is crucial for some enterprises. While the group previously utilized metal jars and other straightforward structures, they battled to find an area that could make the most of holographic interferometry. Be that as it may, the carrier business came on board rapidly, fully backed by teachers of acoustics.

Holographic testing requires a huge starting venture, adding an impressive expense for items. Carriers would put resources into this, as any disappointment would be bigger than the first expense. Stream motors vibrate a great deal, and high cycle exhaustion is a significant wellspring of disappointment for the edges. They are intended to have resonances that are not energized at the rapid pace of activity. Holography provided a method for visualizing mode shapes and validating numerical investigations.

The high effectiveness of a fly motor relies on the restricted hole between sharp edge tips and the motor packaging. An abradable material is attached to the motor housings. In the event that the pivoting edges contact the packaging from any deformity, they will simply scratch away some material and not sever it. In the event that there are spots where the seal isn’t all around clung to the packaging, these might be taken out by the scratching cutting edges and result in more unfortunate motor productivity. Ultrasonic commotion shows disbanded regions as dim spots during holographic testing of a packaging fragment.

The transition to advanced holographic interferometry has been inescapable, given the mechanical improvements of the last thirty years. There is no question that there will be further improvements in this field from here on out, but the creator can’t rest assured where it will take us.

More information: Karl A. Stetson, The discovery of holographic interferometry, its development and applications, Light: Advanced Manufacturing (2022). DOI: 10.37188/lam.2022.002