Another technique for reusing colored plastics has been created by researchers at Cardiff College.

The cycle, which separates shaded polymers, the foremost part of plastics, into their unique parts, could prompt a roundabout plastic reusing economy, diminishing contamination ashore and in our seas, the specialists guarantee.

Broadly utilized in drink bottles, food bundling, apparel, and hardware, colored plastics can be broken down and remolded into new items, yet added substances or colorants can’t be eliminated in current reusing processes.

To stay away from this technique for downcycling, where reused plastic is of lower quality than the first material, the Cardiff group utilized a substance cycle called depolymerization.

“Our current recycling economy only allows plastics and polymers to be recycled a limited number of times before they are disposed of in a landfill or incinerated. This is a significant environmental challenge.”

Dr. Ben Ward, Senior Lecturer in Inorganic Chemistry at Cardiff University,

Dr. Ben Ward, Senior Speaker in Inorganic Science at Cardiff College, said, “Our ongoing reusing economy just permits plastics and polymers to be reused a limited number of times, after which they go to landfills or are burned. This is an enormous ecological test.”

Likewise, an issue for industry is the need to reuse and reuse colored polymers that are restricted by added substances that influence the quality and shade of reused items.”

“We’ve tended to this in our concentrate by taking hued polymers, undoing them, segregating the monomers, and yet again making them into unadulterated, white polymers. This is whenever that first has at any point been accomplished, and it goes right to the core of handling the issue of plastic reusing.”

Utilizing a reactor situated in the labs at Cardiff College’s School of Science, the group picked explicit particles known as monomers to make plastics that are solid and stable while including recyclability as a component of the sub-atomic plan process.

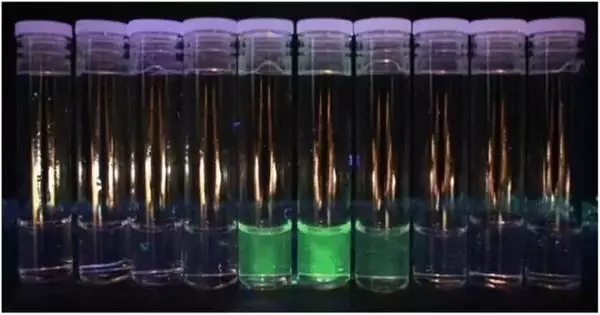

Further monomers were added to the reactor to give the plastic a tone while keeping up with the same properties as the base materials.

Through a compound cycle called depolymerization, the group had the option to undo their items, returning them to the first monomers.

They found that the varieties could be eliminated during the depolymerization interaction, making the plastics recyclable and more economical.

Dr. Ward added, “We’re showing that this is an instrument by which you can reuse plastics endlessly and that innovation simply doesn’t exist for conventional plastics.”

“While industry doesn’t at present have the framework to utilize our way to deal with plastics reusing, we’re showing synthetic reasonability, laying the standard from which this should be possible later on.”

The group is presently attempting to refine the cycle further and make it more financially savvy, as well as guarantee that these new polymers can be handled for use in true items.

The paper is distributed in the journal Polymer Science.

More information: Taylor B. Young et al, Chemically recyclable fluorescent polyesters via the ring-opening copolymerization of epoxides and anhydrides, Polymer Chemistry (2023). DOI: 10.1039/D3PY00209H