Just a small part of the material that could be transformed into new plastic is right now being reused. Analysts at Chalmers have now shown the way that the carbon iotas in blended waste can supplant all fossil natural substances in the creation of new plastic. The reusing strategy is roused by the normal carbon cycle and could kill the environmental effect of plastic materials or even clean the quality of carbon dioxide.

“There are sufficient carbon iotas in waste to address the issues of all worldwide plastic creation. Utilizing these iotas, we can decouple new plastic items from the stock of virgin fossil natural substances. Assuming the cycle is fueled by sustainable power, we get plastic items with over 95% lower environmental influence than those created today, which really implies negative outflows for the whole framework, “says Henrik Thunman, Professor of Energy Technology at Chalmers University of Technology and one of the creators of the review distributed in the Journal of Cleaner Production.

“Waste contains enough carbon atoms to meet the needs of all world plastic manufacture.” We can detach new plastic goods from the availability of virgin fossil raw resources by using these atoms. If the process is fueled by renewable energy, we also receive plastic items that have a more than 95 percent lower climate impact than those produced now, implying that the entire system emits less carbon.”

Henrik Thunman, Professor of Energy Technology at Chalmers University of Technology

To accomplish round cycles, we want to utilize the assets currently being used in the public eye. Henrik Thunman and his exploration group need to zero in on a significant asset that frequently disintegrates today: the carbon iotas in our waste, which are presently burned or end up in landfills as opposed to being reused. This is made possible by advances that focus on the carbon contained in plastic, paper, and wood squanders, regardless of food buildups, to create a natural substance for the creation of plastics with the same assortment and quality as those currently delivered from fossil unrefined components.

Very much like nature.

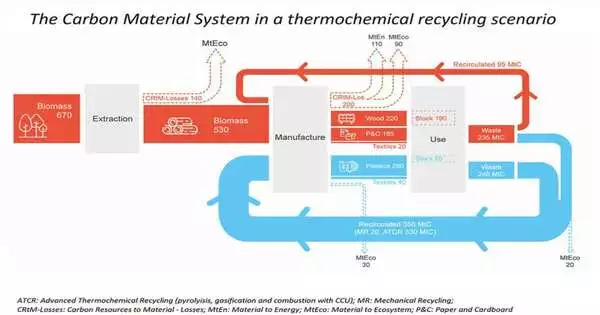

Current plastic reusing techniques can supplant something like 15-20% of the fossil natural substances expected to fulfill society’s need for plastic. The high-level techniques proposed by the analysts depend on thermochemical advances and include the waste being warmed to 600–800 degrees Celsius. The waste then transforms into a gas, which after the expansion of hydrogen, can supplant the building blocks of plastics. Utilizing this reusing strategy could decouple new plastic items from the stock of new fossil natural substances.

The scientists behind the review are fostering a thermochemical reusing strategy that creates a gas that can then be utilized as a natural substance in similar plants in which plastic items are presently being produced using fossil oil or gas. Various sorts of waste, for example, old plastic items and paper cups, regardless of food deposits, are placed into the reactors at the Chalmers Power Central.

“The way to greater reusing is to see leftover waste in an entirely different manner: as a natural substance loaded with helpful carbon iotas.” “The waste then gets worth, and you can make monetary designs to gather and involve the material as a natural substance around the world,” says Henrik Thunman.

Chalmers University of Technology

The rules of the interaction are roused by the normal carbon cycle. Plants are separated into carbon dioxide when they wilt, and carbon dioxide, involving the sun as an energy source and photosynthesis, then makes new plants.

“In any case, our innovation varies from the manner in which it works in nature since we don’t need to take the diversion through the air to flow the carbon as carbon dioxide. All the carbon iotas we want for our plastic creation can be seen as in our waste and can be reused utilizing intensity and power, “says Henrik Thunman.

The analysts’ estimations show that the energy to power such cycles can be taken from sustainable sources, for example, sun-based, wind or hydro power, or by consuming biomass, and they will be more energy-effective than the frameworks being used today. It is also possible to remove excess heat from reusing processes, which would, in a round framework, compensate for the intensity creation now obtained from waste burning while also killing the carbon dioxide outflows related to energy recuperation.

Can supplant fossil natural substances.

The exploration has been done as a feature of the FUTNERC project. The analysts have demonstrated that the cycle can work as a team with plastics producer Borealis in Stenungsund, Sweden, where they have checked the outcomes and demonstrated the way that the natural substance can be utilized to make plastic, supplanting the fossil unrefined components utilized today.

“We want to make a round economy for plastics.” Our plastic items are vital to the change to a feasible society, so we must help research like this. We currently have projects that create circularity for our plastic items, yet more arrangements are required. Hence, we are satisfied with these great outcomes, which can assist in presenting us a bit nearer to our objective, “says Anders Fröberg, CEO of Borealis AB.

The review, “Co-reusing of normal and engineered carbon materials for a feasible round economy,” was published in the Journal of Cleaner Production.

More information: Isabel Cañete Vela et al, Co-recycling of natural and synthetic carbon materials for a sustainable circular economy, Journal of Cleaner Production (2022). DOI: 10.1016/j.jclepro.2022.132674