The wastewater depleting from huge pools of sewage sludge can possibly assume a part in more feasible farming, as per natural scientists at Drexel College.

Another study, looking at a method for removing odor salts from wastewater and converting it into manure, suggests that it is not only feasible, but could also help with lessening the natural and energy impacts of compost creation—and could potentially provide an income stream to utilities and water treatment offices.

A feasible nitrogen source

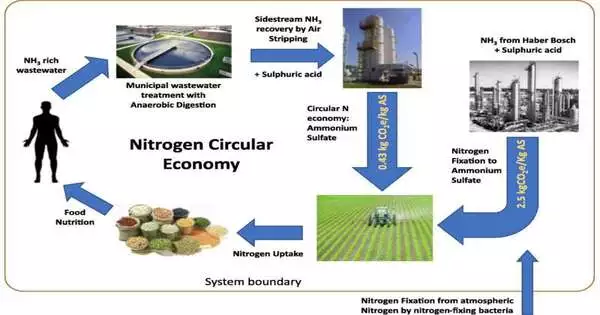

The creation of nitrogen for manure is an energy-intensive cycle and accounts for almost 2% of worldwide carbon dioxide outflows. Over the past quite a while, scientists have investigated options in contrast to the Haber-Bosch nitrogen creation process, which has been the norm for over 100 years. One promising opportunity, as of late raised by some water utility suppliers, is gathering nitrogen from the waste alkali pulled from water during treatment.

“Recovering nitrogen from wastewater would be a better option than the Haber-Bosch process because it creates a “round nitrogen economy,” said Patrick Gurian, Ph.D., a professor in the School of Design who helped lead the study, which was recently published in the diary Study of the All-Out Climate.

“This means we’re utilizing existing nitrogen rather than expending energy and emitting greenhouse gases to harvest nitrogen from the atmosphere, which is a more sustainable technique for agriculture and could become a revenue source for utilities.”

Patrick Gurian, Ph.D., a professor in the College of Engineering

“This implies we are reusing existing nitrogen instead of using energy and creating ozone-harming substances to reap nitrogen from the air, which is a more feasible practice for farming and could turn into a wellspring of income for utilities.”

A cleaner method for cleaning

Under the Perfect Water Demonstration of 1972 civil water treatment offices have been tested to satisfy water quality guidelines for water that they release into streams. Progressively smelling salts is viewed as both a worry for oceanic conditions as raised degrees of alkali can bring about excess of vegetation in streams and waterways which can imperil fish species. The choices for eliminating alkali are by and large reality consuming and can be energy-serious endeavors.

One choice being investigated by a few offices in North America and Europe is a cycle called air-stripping. It eliminates smelling salts by raising the temperature and pH of the water to the point of changing the compound into a gas, which can then be gathered in a concentrated form as ammonium sulfate.

Yet, settling on making the venture to switch over completely to air-stripping requires an intricate report—ccalled a lifecycle examination—oof its mechanical and monetary suitability.

Investigating the choice

The group, led by Gurian and Sabrina Spatari, Ph.D., from the Technion Israel Foundation for Innovation, routinely plays out these examinations to consider the full natural and monetary effects of different choices for reusing and recycling waste or side-stream items as feasible arrangements. Their examination of this wastewater situation suggests there is a reciprocal relationship that could bring about a more feasible way for the two ranchers and the water board specialists.

“Our research identifies a significant potential for natural relief and financial gain from implementing air-stripping innovation at wastewater treatment plants for producing smelling salts and sulfate manure,” they wrote.

“Aside from the attractiveness of smelling salt sulfate production, the advantage of lowering the alkali load in the side-stream before it is reused into the wastewater stream at the wastewater treatment plant provides an additional defense against taking on air stripping.”

Utilizing information from Philadelphia’s water treatment office and a few others across North America and Europe, the group led its lifecycle evaluation and monetary possibility studies. They considered factors ranging from the cost of installing and maintaining an air-stripping framework to the alkali concentration and flow rate of the wastewater, to the sources of energy used to drive the assortment and change process, to the creation and transportation costs, as well as the market cost, of manure synthetics.

Promising outcomes

According to life-cycle analysis findings, air-stripping emits five to ten times less ozone-harming substance than the Haber-Bosch nitrogen-creating interaction and consumes five to ten times less energy.

According to a monetary viewpoint, the general expense of creating manure synthetics from wastewater is low enough that the maker could sell them at a cost in excess of multiple times lower than Haber-Bosch-delivered synthetics yet equal the initial investment.

“Our review proposes that recuperating alkali can be savvy even at low focus,” they write. “However, high alkali concentration is earth friendly, and can help minor production of ammonium sulfate with a lower natural impact, particularly for life cycle energy, ozone harming substance outflows, and a few human and environmental wellbeing markers, when contrasted with Haber-Bosch creation.”

Also, the review proposes that water treatment offices might appreciate energy reserve funds via air-stripping the alkali to lessen levels before the water reenters the waste treatment process. This is on the grounds that it would cut the time and handling expected to treat the water and fits in well with relaxing cycles that help slow compound statements on the treatment plant framework.

While the group recognizes that air-stripping would produce manure in more modest amounts than the modern Haber-Bosch process, having the option to gather and reuse any amount of assets assists with working on the manageability of business farming and keeps them from becoming water poisons.

“This shows that air-stripping for the recuperation of ammonium sulfate could be a little step—yyet a significant one—ttoward recuperating and reusing the huge measure of nitrogen we use to support worldwide farming,” Spatari said.

“Also, altogether, it presents an option for compound creation that doesn’t have a similar degree of harmful natural and human wellbeing impacts as the ongoing system.” This exploration proposes that water utility suppliers could likewise consider putting resources into advances that would catch phosphorous and reuse it for rural use.

More information: Saurajyoti Kar et al, Life cycle assessment and techno-economic analysis of nitrogen recovery by ammonia air-stripping from wastewater treatment, Science of The Total Environment (2022). DOI: 10.1016/j.scitotenv.2022.159499

Journal information: Science of the Total Environment