A new report distributed in Nature Hardware examines stretchable graphene-hydrogel interfaces for wearable and implantable bioelectronics.

Stretchable and conductive nanocomposites with precisely delicate, meager, and biocompatible highlights assume imperative roles in creating wearable skin-like gadgets, savvy, delicate robots, and implantable bioelectronics.

Albeit a few plan procedures, including surface design, have been accounted for to beat the mechanical jumble between the weak cathodes and stretchable polymers, it is yet to be tested to acknowledge a solid combination of different parts with different functionalities utilizing the current ultrathin stretchable conductive nanocomposites. This is credited to the absence of reasonable conductive nanomaterial frameworks that are viable with easy design procedures.

Laser-actuated graphene (LIG), ordinarily obtained from laser illumination of polyimide (PI), has different unmistakable benefits, for example, effortless advanced designing cycles, similarity with design move draws near, as well as tunable physical and substance elements to deliver different wearable sensors.

“Conventional LIG transfer methods require thicker elastomers or adhesive tapes (>45 μm) for strong interfacial force during peeling-off, which limits conformal bioelectronics applications. To overcome mechanical limitations in transferring LIG to elastomers, a cryogenic transfer technique at -196℃ is used with an ultrathin and sticky polyvinyl alcohol/phytic acid/honey hydrogel.”

Kaichen Xu, corresponding author,

Nonetheless, these multifunctional gadgets are built on adaptable PI substrates or generally thick flexible films, attributable to the mechanical impediments in moving LIG to delicate elastomers. Likewise, the mechanical crisscross between the weak LIG and flexible polymer blocks the stretchability of conductive nanocomposites.

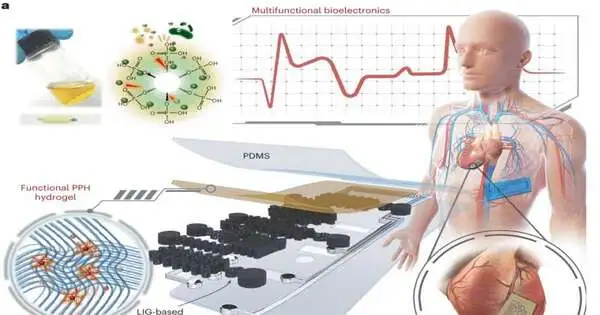

The writers of the article portray an ultrathin, flexible LIG-hydrogel-put-together nanocomposite that is multifunctional with respect to skin and implantable bioelectronics. Another technique is proposed to make an ultrathin-designed LIG-based nanocomposite, which is shaped by cryogenically (77 K) moving LIG to a hydrogel film (least thickness of 1.0 μm). Then the mechanical befuddle between the weak LIG and versatile polymer, which utilizes the hydrogel as an energy dissemination interface and out-of-plane electrical way, is tended to.

Persistently redirected breaks can be prompted in the LIG, prompting a more than five-overlap upgrade in natural stretchability. In general, this exploration gives a feasible methodology to develop ultrathin carbon-hydrogel-based stretchable nanocomposites for coordinated sensor frameworks, empowering different applications in wearable/implantable bioelectronics and human-machine cooperation.

Kaichen Xu, relating creator, noted, “Customary LIG move strategy requires a lot bigger thickness (>45 μm) of elastomers or glue tapes to give serious areas of strength for a power during the stripping off process, impeding the conformal bioelectronics applications. The mechanical limitations in moving LIG to elastomers are overwhelmed by a cryogenic exchange approach at 196 °C utilizing an ultrathin and cement polyvinyl liquor/phytic corrosive/honey (PPH) hydrogel.”

During the quick cooling process, the interfacial restricting energy between imperfect permeable graphene and the solidified water inside the hydrogel is upgraded, as represented by atomic element (MD) computations. Such a sensational expansion in shallow restricting power at 77 K was likewise caught in the 180° stripping test. The greatest transient stripping power of 160 N m-1 at 77 K was noticed, which was a lot higher than that (<10 N m-1) beginning from the autologous grip of PPH at the surrounding temperature.

Besides, the proposed cryogenic exchange methodology permitted the exchange of LIG onto different kinds of cement or non-glue hydrogels, showing the comprehensiveness of this innovation. In any case, just the cement hydrogel framed a precisely steady restricting connection point, particularly under the elastic strain.

Through the simple laser direct composition and cryogenic exchange method, multimodal sensor parts are coordinated as a multifunctional wearable sensor sheet for on-skin in vitro observing. Besides, the ultrathin and biocompatible attributes of the micropatterned LIG-based nanocomposites permit consistent contact with the core of Sprague Dawley (SD) rodents to in situ follow heart signals.

More information: Yuyao Lu et al, Stretchable graphene-hydrogel interfaces for wearable and implantable bioelectronics, Nature Electronics (2023). DOI: 10.1038/s41928-023-01091-y