Another North Carolina State College review, conducted in a joint effort with battery testing specialists at the U.S. Division of Energy’s Oak Edge Public Research Center, demonstrates the way that very short heartbeats from a powerful laser can cause little imperfections in lithium-particle battery materials—surrenders that can improve battery execution.

The strategy, called “nanosecond beat laser tempering,” goes on for just 100 nanoseconds and is produced by a similar sort of laser utilized in current eye medical procedures. Scientists tried the procedure on graphite, a material widely utilized in lithium-particle battery anodes or positive cathodes. They tried the method in clumps of 10 and 80 heartbeats and analyzed the distinctions in the current limit; power is determined by duplicating voltage by current.

Lithium-particle batteries are widely utilized in convenient electronic gadgets and electric vehicles. With additional upgrades, these batteries could significantly affect transportation and be used to stockpile gadgets for sustainable power sources like wind and sunlight.

The review showed various fascinating outcomes, said Jay Narayan, the John C. Fan Family Recognized Seat in Materials Science at NC State, and compared the creator of a paper depicting the work. Narayan spearheaded the utilization of lasers to make and control defects in semiconductors in work spanning over forty years. The work is distributed in the diary, Carbon.

“Because lithium ion has a positive charge, capturing an electron converts it to lithium metal, which you don’t want. Lithium metal emits microscopic wire dendrites from the graphite anode, which can ignite. So you want to prevent a lithium ion from becoming a metal.”

Jay Narayan, the John C. Fan Family Distinguished Chair in Materials Science

“Material deformities can be an irritation; however, in the event that you engineer them accurately, you can make them a benefit,” he said. “This strategy opens the entryway, as it were, for lithium particles, so it improves the ongoing limit.” Graphite anodes comprise steps and depressions on a superficial level; making more advances resembles making more entryways for lithium particles to get in and get out, which is useful.

“The strategy likewise creates deserts called opportunities, which are missing particles, and that gives more destinations for lithium particles to go back and forth, which is connected with the ongoing limit.”

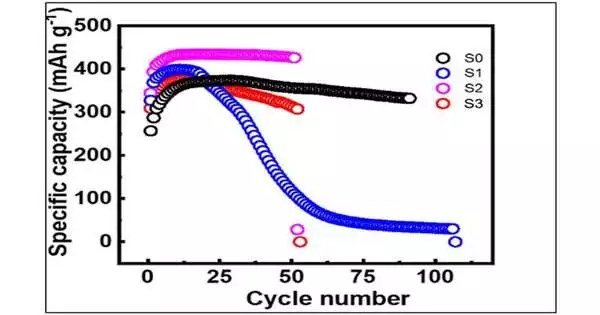

The current limit expanded by 20% when the ideal number of heartbeats was utilized, which was closer to 10 than 80 heartbeats.

The concentrate likewise showed, however, that an overdose of something that is otherwise good can be something terrible, as an excessive number of imperfections in the graphite anodes can prompt issues.

“Lithium particles have a positive charge, so assuming that it catches an electron, it becomes lithium metal, and you don’t need that,” Narayan said. “Lithium metal darts small wire dendrites from the graphite anode and can cause a fire.” So you need to ensure that a lithium particle doesn’t turn into a metal.

According to Narayan, manufacturers should be able to use nanosecond laser strengthening when creating anodes and cathodes, the two terminals found in batteries.

“These powerful lasers exist, and you can treat anodes and cathodes inside a microsecond,” Narayan said. “The cathodes or anodes are made on a sheet, which makes treatment somewhat quick and simple.”

Narayan and associates at the College of Texas–Austin have as of late distributed one more paper that utilized a similar laser method on cathode materials. Distributed in ACS Applied Materials and Connection Points, that study showed laser treatment upgraded cathode materials.

“Then, we are attempting to eliminate the requirement for utilizing more costly materials, for example, cobalt in battery cathodes, to make higher-power and longer-enduring batteries,” Narayan said.

Roger Narayan, a recognized teacher of biomedical design at NC State, co-wrote the paper in carbon alongside its first creator, Nayna Khosla, a NC State graduate undergrad. Xiao-Guang Sun and M. Parans Paranthaman from Oak Edge Public Lab likewise co-wrote the paper.

More information: Nayna Khosla et al, Microstructure and defect engineering of graphite anodes by pulsed laser annealing for enhanced performance of lithium-ion batteries, Carbon (2023). DOI: 10.1016/j.carbon.2023.01.009

Zehao Cui et al, Laser-Assisted Surface Lithium Fluoride Decoration of a Cobalt-Free High-Voltage Spinel LiNi0.5Mn1.5O4 Cathode for Long-Life Lithium-Ion Batteries, ACS Applied Materials & Interfaces (2022). DOI: 10.1021/acsami.2c18918