Around the end of the nineteenth century, Abbe and Rayleigh formed the standards of optical diffraction that restrict the use of optical instruments in the far field, where the distance between the objective and the optical component is far more prominent than the optical frequency.

These standards remained unchallenged for nearly a century until new advances in optical technology opened up new avenues for pushing them as far as possible.One such method utilizes centered annular sufficiency collimated lasers radiating with spiral polarization, so inverse course plane waves spread towards a similar point of convergence and cause useful impedance in the optical hub, prompting an even central place where every one of the electric fields is situated in the longitudinal bearing, lined up with the optical hub.

Albeit various earlier examinations endeavored to show the likelihood of breaking the optical diffraction limit by utilizing the alleged longitudinal field, the virtue of these fields has never been sufficiently high to accomplish the best handling goals. From one perspective, the round deviation of a high NA focal point centering is difficult to overcome when using standard optical focal points.However, a large annular collimated bar with a small width and uniform conveyance is required, which is also difficult to recognize by simply impeding the focal region of the bar.In the event that the engaged laser bar is a combination of longitudinal and cross-over fields, the handling goal is decreased.

“The laser beam must be bent into a high quality annular beam in order to generate a high purity longitudinal field. We used a spatial light modulator (SLM) to modify the original collimated Gaussian into a perfect Gaussian beam before converting it to a narrow annular beam.”

Professor Lin Li and Dr. Olivier Allegre from the Laser Processing Research Center

In another paper distributed in Light: Science and Applications, a group of researchers led by Teacher Lin Li and Dr. Olivier Allegre from the Laser Handling Exploration Center at the College of Manchester, U.K., has fostered a clever strategy to tentatively show a longitudinal femtosecond laser field (i.e., lined up with the optical hub) with an uncommonly high virtue (94.7%) and its connections with cleaned silicon, copper, and sapphire.

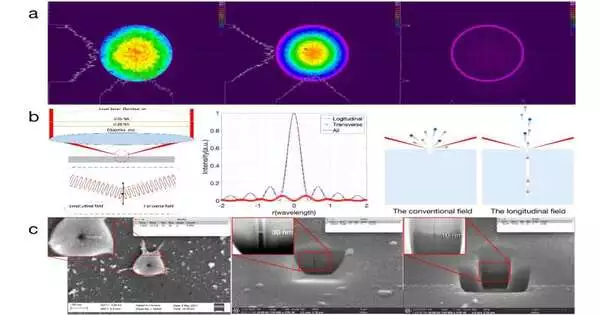

The new optical arrangement is created utilizing a 800 nm-frequency femtosecond laser source and a couple of spatial light modulators (SLMs) in a twofold, four-fold optical plan to tailor the laser light fields and acknowledge great and uniform bar molding to address the round variation of the 0.95 NA objective focal point. The tests included centering the bar first using an aplanatic 0.75 NA focal point to affirm the presence of the longitudinal fields and afterward using a 0.95 NA focal point to additionally comprehend the qualities of the engaged longitudinal fields and their impacts on laser materials handling.

Various polarization states, bar force dispersion, and wavefront removal profiles were explored, and the outcomes were contrasted with hypothetical models of the longitudinal field. Material handling with a goal (10 nm, i.e., l/80) past the far-field diffraction limit at the infrared laser frequency of 800 nm was shown on cleaned sapphire in air.

Dr. Zhaoqing Li said, “To create a high-quality longitudinal field, the laser bar should be molded into a great annular bar.” “We molded the first, right off the bat, collimated Gaussian into an ideal Gaussian bar and afterward changed it over completely to a slim annular bar by utilizing a spatial light modulator (SLM).”

“Before centering the annular laser bar with spiral polarization and a 0.95 NA objective focal point, the round variation should be precisely revised to ensure that the laser bar is engaged into an equivalent plane.”We understood it by utilizing another spatial light modulator (SLM), so we could accomplish the great longitudinal field with a virtue of up to 94.7%.

“By zeroing in the longitudinal field on sapphire, openings with a very small width were made, which is a lot more modest than the recently distributed results in assessing areas of strength for laser materials connection processes.”

“A centered particle bar (Lie) cross-segment was led to test the cross-area qualities of these small openings.””For a 30 nm-wide opening, the profundity was north of 500 nm with a zero shape.

Dr. Olivier Allegre said, “The tiny element size and high profundity to viewpoint proportion with equal opening walls we saw in this study could show that the material expulsion system prompted with the longitudinal field is generally not the same as those incited with a cross-over direct polarization.” This peculiarity is seldom found in laser materials handling at this scale with a solitary heartbeat.

“In the trial results shown in this paper, the electrical field is at the laser bar hub. The laser bar with the longitudinal field could act fairly like an atom smasher and empower the electron (with negative charge) and particle (with positive charge) to be shot out more than in a standard Coulombic blast. “The profound openings created in our tests show the chance of electron speed increase and charge polarization in the openings for material expulsion.”

Teacher Lin Li said, “The meaning of this examination is the demonstration of super-goal materials handling with an infrared laser bar, which breaks the optical diffraction limit in the far field, while most past methodologies are either founded on expensive, outrageously bright (EUV) laser frequencies that work inside the optical diffraction limit or on the utilization of close-to-handle optics that make the functioning distance excessively near to be basically helpful.” “The high viewpoint proportion of the laser-handled highlights brings up another material expulsion system.”

More information: Zhaoqing Li et al, Realising high aspect ratio 10 nm feature size in laser materials processing in air at 800 nm wavelength in the far-field by creating a high purity longitudinal light field at focus, Light: Science & Applications (2022). DOI: 10.1038/s41377-022-00962-x

Journal information: Light: Science & Applications