Electronic structure, or the arrangement of electrons in matter, is important for both fundamental and applied research in areas like drug design and energy storage. However, the development of these technologies has been stymied for a long time by the absence of a simulation method that provides both high fidelity and scalability across various time and length scales.

A pioneering machine learning-based simulation method has been developed by Sandia National Laboratories in Albuquerque, New Mexico, United States, and the Center for Advanced Systems Understanding (CASUS) at the Helmholtz-Zentrum Dresden-Rossendorf (HZDR) in Görlitz, Germany.

The Materials Learning Algorithms (MALA) software stack they use gives them access to length scales that were previously out of reach. The research has been published in the NPJ Computational Materials journal.

Electrons are rudimentary particles of principal significance. Their quantum mechanical communications with each other and with nuclear cores lead to a large number of peculiarities in science and materials science. The reactivity of molecules, the structure and energy transport within planets, and the mechanisms of material failure are all revealed by comprehending and controlling the electronic structure of matter.

Utilizing the capabilities of high-performance computing, computational modeling and simulation are increasingly being utilized to address scientific issues. Nonetheless, a huge deterrent to accomplishing practical reproductions with quantum accuracy is the absence of a prescient display method that combines high exactness with versatility across various lengths and time scales.

Quantum electronic structure is not included in classical atomistic simulation methods, so their applicability is limited. However, they are capable of handling large and complex systems. In contrast, empirical modeling and parameter fitting, which are examples of first-principles simulation techniques, offer high fidelity but are computationally intensive. For instance, the widely used first-principles method of density functional theory (DFT) exhibits cubic scaling with system size, limiting its predictive capabilities to small scales.

Mix approach in light of profound learning

The group of specialists has currently introduced a clever reproduction technique called the Materials Learning Calculations (MALA) programming stack. A software stack is a collection of algorithms and software components used to create a software application for a specific problem in computer science.

“MALA integrates machine learning with physics-based approaches to predict the electronic structure of materials,” says Lenz Fiedler, a Ph.D. student and key developer of MALA at CASUS. An established machine learning technique known as deep learning is used to accurately predict local quantities, and physics algorithms are used to compute global quantities of interest.”

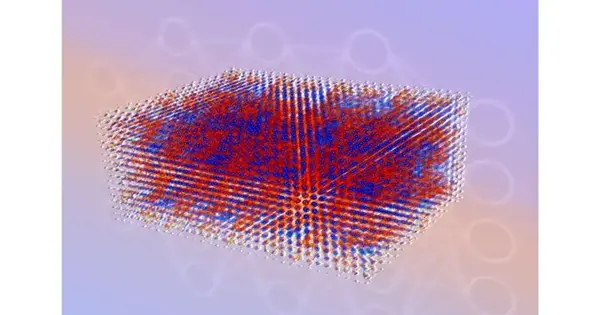

The MALA programming stack takes the plan of particles in space as information and produces fingerprints known as bispectrum parts, which encode the spatial course of action of iotas around a Cartesian matrix point. Based on this atomic neighborhood, the MALA machine learning model is trained to predict the electronic structure. A huge benefit of MALA is its AI model’s capacity to be free of framework size, permitting it to be prepared on information from small frameworks and conveyed at any scale.

In their distribution, the group of analysts displayed the exceptional adequacy of this system. In comparison to conventional algorithms, they were able to speed up smaller system sizes of up to a few thousand atoms by more than 1,000 times. The team also demonstrated that MALA could accurately calculate electronic structure on a large scale with more than 100,000 atoms. Notably, this achievement was made possible with little computational effort, highlighting the drawbacks of traditional DFT codes.

Attila Cangi, the Acting Division Head of Issue under Outrageous Circumstances at CASUS, makes sense of, “As the framework size increments and more iotas are involved, DFT computations become unreasonable, though MALA’s speed advantage keeps on developing. Mala’s ability to operate in local atomic environments is its main innovation. This makes it possible to make precise numerical predictions that are minimally influenced by system size. This groundbreaking achievement opens up previously unimaginable computational possibilities.”

Help for applied research is anticipated.

Cangi intends to push the limits of electronic construction estimation by utilizing AI. “We guess that MALA will start a change in electronic construction computations, as we currently have a technique to mimic fundamentally bigger frameworks at a phenomenal speed. Later on, specialists will actually want to address an expansive scope of cultural difficulties in view of a fundamentally better pattern, including growing new immunizations and novel materials for energy capacity, leading enormous scope reproductions of semiconductor gadgets, concentrating on material deformities, and investigating compound responses for changing over the air ozone-harming substance carbon dioxide into environment-friendly minerals.”

Besides, MALA’s methodology is especially appropriate for superior execution processing (HPC). As the framework size increases, MALA empowers autonomous handling on the computational network it uses, successfully utilizing HPC assets, especially graphical handling units.

“MALA’s algorithm for electronic structure calculations maps well to modern HPC systems with distributed accelerators,” says Siva Rajamanickam, a staff scientist at Sandia National Laboratories who is an expert in parallel computing. MALA is an excellent match for scalable machine learning on HPC resources due to its ability to decompose work and execute in parallel at various grid points across various accelerators, resulting in electronic structure calculations of unparalleled speed and efficiency.”

More information: Lenz Fiedler et al, Predicting electronic structures at any length scale with machine learning, npj Computational Materials (2023). DOI: 10.1038/s41524-023-01070-z