Analysts have found that they have some control over the tenacity of glue wraps by utilizing ultrasound waves and air pockets. This advancement could prompt new advances in clinical glues, particularly in situations where cements are hard to apply, like on wet skin.

“Wraps, pastes, and stickers are normal bioadhesives that are utilized at home or in centers. In any case, they don’t normally stick well on wet skin. It’s additionally difficult to control where they are applied and the strength and span of the shaped bond, “says McGill University Professor Jianyu Li, who led the examination group of designers, physicists, scientists, and clinicians.”

“We were shocked to find that by just messing with ultrasonic force, we have some control over the tenacity of glue wraps on many tissues,” says lead creator Zhenwei Ma, a previous understudy of Professor Li and presently a Killam Postdoctoral Fellow at the University of British Columbia.

“We were surprised to discover that by just adjusting the ultrasonic strength, we can accurately control the stickiness of adhesive bandages on a variety of tissues.”

Zhenwei Ma, a former student of Professor Li at the University of British Columbia.

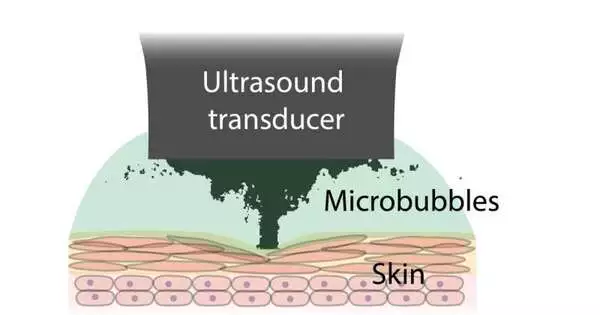

Ultrasound incited bubbles control tenacity.

In a joint effort with physicists Professor Outi Supponen and Claire Bourquard from the Institute of Fluid Dynamics at ETH Zurich, the group tried different things with ultrasound prompted microbubbles to make glue stickier. “The ultrasound prompts numerous microbubbles, which briefly drive the glue into the skin for more grounded bioadhesion,” says Professor Supponen. “We could use a hypothetical display to predict exactly where the bond will occur.”

Their study, published in the journal Science, demonstrates that the glues are compatible with living tissue in rodents. The glues could also be used to transport drugs through the skin. “This outlook-changing innovation will have extraordinary ramifications in many parts of medication,” explains University of British Columbia Professor Zu-hua Gao. “We’re extremely eager to decipher this innovation for applications in centers for tissue repair, disease treatment, and accurate medication.”

We envision the broad impact of our bioadhesive innovation in wearable gadgets, wound administration, and regenerative medication by combining mechanics, materials, and biomedical design,” says Professor Li, who is also a Canada Research Chair in Biomaterials and Musculoskeletal Health.

More information: Zhenwei Ma et al, Controlled tough bioadhesion mediated by ultrasound, Science (2022). DOI: 10.1126/science.abn8699

Journal information: Science