Expulsion-based 3D printing of bio solids, or “bioprinting,” is a promising way to deal with creating patient-explicit, tissue-designed joins. In any case, a significant test in bioprinting is that most currently utilized materials come up short on flexibility to be utilized in many applications.

New nanotechnology has been created by a group of scientists from Texas A & M University that uses colloidal connections of nanoparticles to print complex calculations that can copy tissue and organ structure. The group, led by Dr. Akhilesh Gaharwar, academic partner and Presidential Impact Fellow in the Department of Biomedical Engineering, has presented colloidal arrangements of 2D nanosilicates as a stage innovation to print complex designs.

“Nanosilicates’ adaptability could lead to their widespread use in the domains of medical devices, tissue engineering, medication delivery, and additive manufacturing.”

Dr. Akhilesh Gaharwar, associate professor

2D nanosilicates are plate molded inorganic nanoparticles 20 to 50 nanometers in width and 1 to 2 nanometers in thickness. These nanosilicates structure a “place-of-cards” structure over a specific focus in water, known as a colloidal arrangement.

These colloidal arrangements have engaging properties while concentrating on the twisting of a material, for example, expanded thickness and yield pressure as well as shear diminishing, where consistency lessens under strain, and thixotropic conduct, where a material distorts because of applied power. The Gaharwar Laboratory uses the rheological properties of these nanosilicates for expulsion-based 3D printing.

The aftereffects of the group’s exploration were distributed in the diary Bioprinting.

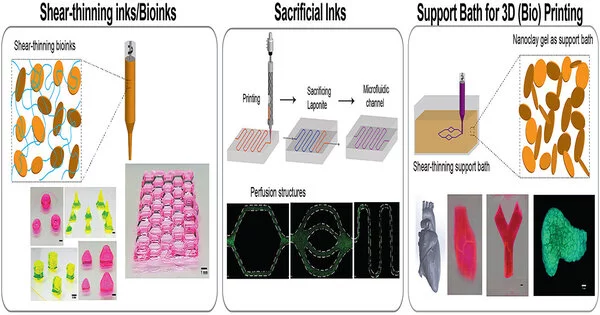

A few significant difficulties in expulsion-based 3D printing are the failure to print tall and complex designs, as delicate materials stream under gravity and can’t frame self-supporting designs. To overcome these difficulties, scientists utilized colloidal nanosilicates and showed them as a stage innovation for bioprinting utilizing three unique methodologies.

In the main methodology, Satyam Rajput, a biomedical design alumni understudy in the Gaharwar Laboratory and the lead creator of the paper, planned a shear-diminishing ink made out of nanosilicates and water-solvent polymers, for example, agarose, alginate, kappa-carrageenan, gelatin, gelatin methacryloyl, polyethylene glycol, and N-isopropyl acrylamide. The printable ink plan showed great shape loyalty.

In the subsequent methodology, the group utilized nanosilicates as a conciliatory ink, an instrument intended to fizzle and be taken out, to plan microfluidic gadgets for in vitro illness display. These perfusable gadgets can be utilized for different applications to copy and concentrate on vascular physiology and liquid mechanics, illness models, tissue association and capability, helpful tissue design, and 3D-cell culture models and screening drugs.

In the third methodology, the scientists used a colloidal nanosilicate gel as a help shower for 3D printing by invalidating the surface strain and gravitational powers. For example, a bifurcated vessel, femur, meniscus, DNA twofold helix, heart and trileaflet valve were printed inside the help shower.

“The flexibility of nanosilicates could be broadly taken on in the fields of added substance producing, tissue designing, drug conveyance, and clinical gadgets,” Gaharwar said.

More information: Satyam Rajput et al, 2D Nanosilicate for additive manufacturing: Rheological modifier, sacrificial ink and support bath, Bioprinting (2022). DOI: 10.1016/j.bprint.2021.e00187