In the most recent development in nano- and miniature-architected materials, engineers at Caltech have fostered another material produced using various interconnected microscale hits.

The bunches make the material far harder than indistinguishably organized but unknotted materials: they retain more energy and can twist more while still having the option to get back to their unique shape. These new hitching materials might find applications in biomedicine as well as in aviation applications because of their toughness, conceivable biocompatibility, and outrageous deformability.

“The capacity to defeat the general compromise between material deformability and elastic strength [the capacity to be extended without breaking] offers better approaches to designing gadgets that are very adaptable, solid, and can work in outrageous circumstances,” says previous Caltech graduate understudy Widianto P. Moestopo, presently at Lawrence Livermore National Laboratory. Moestopo is the lead creator of a paper on nanoscale hits that was distributed on Walk 8 in Science Advances.

“The ability to overcome the conventional trade-off between material deformability and tensile toughness the ability to stretch without breaking opens up new avenues for designing devices that are exceedingly flexible, robust, and capable of operating under harsh environments,”

Widianto P. Moestopo, now at Lawrence Livermore National Laboratory.

Moestopo fostered the material in the lab of Julia R. Greer, Ruben F. also, Donna Mettler, Teacher of Materials Science, Mechanics, and Clinical Designing; Fletcher Jones, Establishment Head of the Kavli Nanoscience Foundation; and the senior creator of the paper. Greer is at the very front of the formation of such nano-architected materials, or materials whose construction is planned and coordinated at a nanometer scale and that subsequently show uncommon, frequently astounding properties.

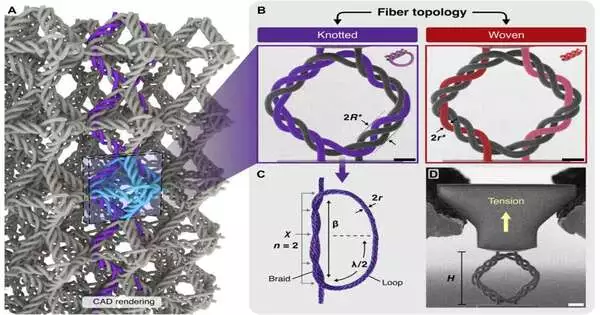

The rigidity of a material developed with microscale hitches (left), contrasted with that of a material that needs ties yet is generally basically indistinguishable (right), Credit: Caltech

“Setting out on understanding what the bunches would mean for the mechanical reaction of miniature-architected materials was an out-of-the-box thought,” Greer says. “We had done a broad examination, concentrating on the mechanical twisting of numerous different kinds of miniature materials, for instance, grids and woven materials. Wandering into the universe of bunches permitted us to acquire further bits of knowledge about the job of erosion and energy dispersal and ended up being significant.”

Each bunch is around 70 micrometers in length and width, and every fiber has a sweep of around 1.7 micrometers (around 100th of the range of a human hair). While these are not the tiniest bunches made — in 2017, scientists tied a bunch produced using a singular strand of particles — this addresses the first occasion when a material made out of various bunches at this scale has at any point been made. Further, it shows the expected benefit of incorporating these nanoscale hits in a material — for instance, for stitching or tying in biomedicine.

The tied materials, which were made out of polymers, displayed a ductile durability that far outperformed materials that are unknotted yet generally basically indistinguishable, including ones where individual strands are joined rather than hitched. When contrasted with their unknotted partners, the hitched materials ingest 92% more energy and require over two times as much strain to snap when pulled.

The bunches were not tied yet but rather made in a hitched state by utilizing progressed high-goal 3D lithography fit for delivering structures at the nanoscale. The examples itemized in the Science Advances paper contain basic bunches — an overhand bunch with an additional bend that gives extra erosion to assimilate extra energy while the material is extended. Later on, the group intends to investigate materials built from additional complicated bunches.

Moestopo’s advantage in tangles outgrew the research he was leading in 2020 during the Coronavirus lockdowns. “I ran over certain works from scientists who are concentrating on the mechanics of actual bunches rather than hitches in a simply numerical sense. I don’t view myself as a climber, a mariner, or a mathematician; however, I have tied bunches all through my life, so I thought it merited attempting to embed hitches into my plans,” he says.

The paper has a facetious title: “Bunches are Not in Vain: Plan, Properties, and Geography of Various Leveled Entwined Microarchitected Materials.” Naval Exploration.

More information: Widianto P. Moestopo et al, Knots are not for naught: Design, properties, and topology of hierarchical intertwined microarchitected materials, Science Advances (2023). DOI: 10.1126/sciadv.ade6725