Researchers from the Division of Mechanical Design at Osaka College presented a technique for assembling complex microrobots driven by compound energy that involves in situ coordination. By 3D-printing and collecting the mechanical designs and actuators of microrobots inside a microfluidic chip, subsequent microrobots were able to perform desired roles such as moving or grasping.This work might assist with understanding the vision of microsurgery performed by independent robots.

As clinical innovation progresses, progressively confounding medical procedures that were once viewed as inconceivable have become realities. Nonetheless, we are still far from a guaranteed future wherein microrobots flowing through a patient’s body can carry out techniques like microsurgery or malignant growth cell disposal.

“Our in situ integration of actuators and mechanical components enhanced the flexibility and efficiency of microrobot manufacture, which may aid in solving the currently tough problem of mass production,”

Keisuke Morishima

In spite of the fact that nanotech techniques have proactively excelled at delivering minuscule designs, it remains a test to control and gather these constituent parts into utilitarian complex robots, particularly while attempting to create them at a mass scale. Thus, the get-together, reconciliation, and reconfiguration of little mechanical parts, and particularly versatile actuators driven by compound energy, remains a troublesome and tedious cycle.

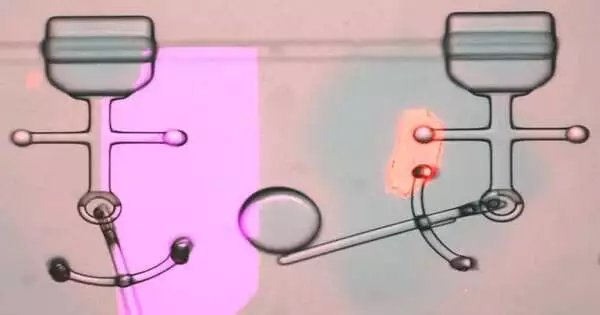

Microrobots created in situ.

Presently, a group of scientists, including Morishima and Wang at Osaka College, Hiratsuka at the Japan Progressed Foundation of Science and Innovation (JAIST), and Nitta at Gifu College, have fostered another technique for 3D-printing microrobots with numerous part modules inside the equivalent microfluidic chip. Delicate microrobot structures are delivered by focusing laser light to solidify a photographically inducible biocompatible hydrogel, poly (ethylene glycol) diacrylate.

“As of late, microrobot advancement has been progressing from hard and inflexible designs to delicate and adaptable structures,” first creator Yingzhe Wang says. The stepwise cycle was rearranged and smoothed out using contrasted and previous techniques gathered from various modules set up or in situ.

The group’s mechanical production system approach allowed them to consolidate different modules, like joints, grippers, or counterfeit muscles, into a single gadget. The effective reconciliation of various capabilities may allow for a wide assortment of microrobots and versatile large-scale manufacturing. For this work, the scientists showed a few distinct sorts, including a gripper, a fish, and a robot arm.

on-chip microrobots for microfluidic applications.

“Our in situ combination of actuators and mechanical designs worked on the adaptability and effectiveness of microrobot creation, which might assist with understanding the troublesome issue of large-scale manufacturing right now,” senior creator Keisuke Morishima says. Notwithstanding their medical service applications, these robots can likewise help in the creation of yet more mind-boggling robots by acting as microfluidic valves or controllers.

More information: Yingzhe Wang et al, In situ integrated microrobots driven by artificial muscles built from biomolecular motors, Science Robotics (2022). DOI: 10.1126/scirobotics.aba8212

Journal information: Science Robotics