For example, nanomolding of topological nanowires could speed the revelation of new materials for applications, for example, quantum processing, microelectronics, and clean-energy impetuses, as indicated by an article co-created by Judy Cha, teacher of materials science and design at Cornell.

Topological materials are esteemed for their extraordinary capacity to have various properties at their surfaces and edges, and these surface properties can be improved by designing the materials at the nanoscale. The problem for researchers is that customary strategies for creating nanowires are slow and don’t offer an elevated degree of accuracy.

“Scholars have anticipated that about a fourth of all realized inorganic gems might be topological,” Cha said. “We’re talking a huge number of mixtures, so the traditional strategy for making these gems is only contrary concerning screening them to search for test topological materials for explicit applications.”

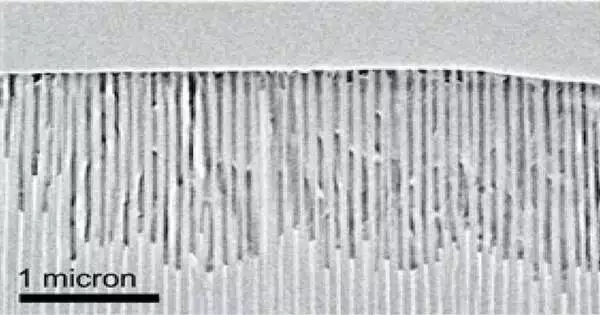

However, nanomolding, in which a mass of polycrystalline feedstock is squeezed into a nanostructured shape at a raised temperature to frame nanowires, could provide an answer. Writing in APL Materials, Cha and postdoctoral partner Mehrdad Kiani make sense of nanomolding and offer a few benefits over existing combination strategies for nanoscale materials.

“Because we’re dealing with tens of thousands of chemicals, the traditional process of producing these crystals is simply incompatible in terms of screening them for test topological materials for certain applications.”

Judy Cha, professor of materials science and engineering at Cornell.

“In contrast to customary hierarchical and base-up creation strategies, nanomolding requires negligible enhancement of exploratory boundaries and can deal with a wide assortment of topological mixtures, in this way empowering high throughput manufacture of topological nanowires. The created nanowires are single translucent and imperfection free and can have high viewpoint proportions more prominent than 1,000, “compose Cha and Kiani.

Although nanomolding has recently been used for metallic material frameworks, Cha and her research team are among the first to apply it to topological materials.And keeping in mind that, on a fundamental level, nanomolding conveys every one of the qualities needed in a topological nanowire, precisely how and why the technique is so fruitful is as yet not completely perceived — an information hole that the Cha Gathering is attempting to fill.

The flow research projects in the Cha Gathering incorporate estimating the electrical properties of nanomolded topological nanowires to benchmark against nanowires delivered with different strategies and concentrating on nuclear dispersion and mechanical movements of iotas during the embellishment cycle. Cha is likewise inviting colleagues keen on the nanowire forms of mixtures that they are exploring.

The examination was additionally highlighted in AIP Scilight.

More information: Mehrdad T. Kiani et al, Nanomolding of topological nanowires, APL Materials (2022). DOI: 10.1063/5.0096400

Ashley Piccone, Nanomolding nanowires for high throughput screening of topological materials, AIP Scilight (2022). DOI: 10.1063/10.0013404