An electron microscope is a type of microscope that illuminates with a beam of accelerated electrons. These are used to study the ultrastructure of a variety of biological and inorganic specimens, including microbes, cells, big molecules, biopsy samples, metals, and crystals. Electron microscopes are frequently used in the industry for quality control and failure analysis.

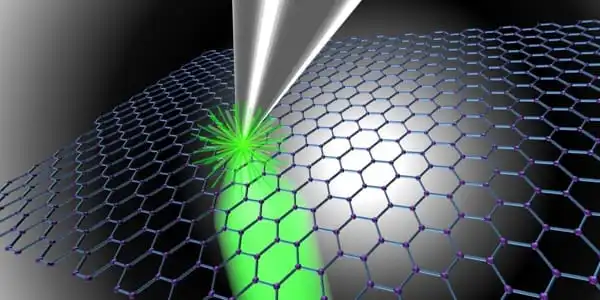

A worldwide team of researchers created a transistor 25,000 times smaller than the width of a human hair using a novel instrument put into an electron microscope. The study, which was published in the journal Science, involved experts from Japan, China, Russia, and Australia who worked on the project for five years.

Professor Dmitri Golberg, co-director of the QUT Centre for Materials Science, who led the research project, described the findings as a “very interesting fundamental discovery” that could pave the way for the future development of tiny transistors for future generations of advanced computing devices. “We demonstrated that it is possible to manipulate the electrical characteristics of a particular carbon nanotube in this work,” Professor Golberg remarked.

Semiconducting carbon nanotubes are promise for producing energy-efficient nanotransistors to build beyond-silicon microprocessors. However, controlling the chirality of individual carbon nanotubes, which controls the atomic geometry and electrical structure, remains a significant issue. We conceived and built carbon nanotube intramolecular transistors by changing the local chirality of a metallic nanotube segment through heating and mechanical strain in this study.

Dr. Dai-Ming Tang

The tiny transistor was generated by simultaneously applying a force and a low voltage that heated a carbon nanotube made up of several layers until the outer tube shells separated, leaving only a single-layer nanotube. The heat and tension then modified the nanotube’s “chilarity,” or the arrangement in which the carbon atoms bonded together to form the single-atomic layer of the nanotube wall. The nanotube was changed into a transistor as a result of the new structure connecting the carbon atoms.

Carbon nanotubes (CNTs) are quasi-one-dimensional materials with distinct properties that are suited for use in electronic systems. Significant progress has been achieved in CNT electronics, and this research has resulted in a doping-free method. Carbon nanotubes (CNTs) have extraordinary physical features such as huge specific surface areas, strong electron conductivity, good chemical inertness, and very high oxidation stability, making them a viable support material for heterogeneous catalysis.

Members of Professor Golberg’s team from Moscow’s National University of Science and Technology developed a theory to explain the changes in the atomic structure and properties observed in the transistor. Dr. Dai-Ming Tang of Japan’s International Center for Materials Nanoarchitectonics, the study’s lead author, stated that the research proved the ability to control the chemical characteristics of the nanotube to create a nanoscale electrical device. Dr. Tang started working on the subject five years ago, while Professor Golberg was in charge of the research group at this center.

“Semiconducting carbon nanotubes are promise for producing energy-efficient nano transistors to build beyond-silicon microprocessors,” stated Dr. Tang. “However, controlling the chirality of individual carbon nanotube, which controls the atomic geometry and electrical structure, remains a significant issue. We conceived and built carbon nanotube intramolecular transistors by changing the local chirality of a metallic nanotube segment through heating and mechanical strain in this study.”

Professor Golberg described the finding as a promising step toward developing beyond-silicon microprocessors by demonstrating the core science of manufacturing the small transistor.

Transistors, which switch and amplify electrical impulses, are frequently referred to as the “building blocks” of all electronic devices, including computers. Apple, for example, claims that the processor that will power future iPhones comprises 15 billion transistors. For decades, the computer industry has been focused on manufacturing smaller and smaller transistors, but silicon has its limitations. Researchers have made tremendous advances in the development of nanotransistors, which are so small that millions of them might fit on the tip of a pin.

“Miniaturization of transistors to the nanoscale scale is a significant problem for the present semiconducting industry and nanotechnology,” Professor Golberg stated. “While not practicable for mass-production of tiny transistors, the current discovery demonstrates a novel fabrication process and opens up a new vista of using thermomechanical treatments of nanotubes to get the smallest transistors with desired features.”