Adaptable gadgets have empowered the planning of sensors, actuators, microfluidics, and hardware on adaptable, conformal, as well as stretchable sublayers for wearable, implantable, or ingestible applications. In any case, these gadgets have altogether different mechanical and organic properties when compared with human tissue and hence can’t be coordinated with the human body.

A group of scientists at Texas A&M University has fostered another class of biomaterial inks that copy the local qualities of profoundly conductive human tissue, similar to skin, which are fundamental for the ink to be utilized in 3D printing.

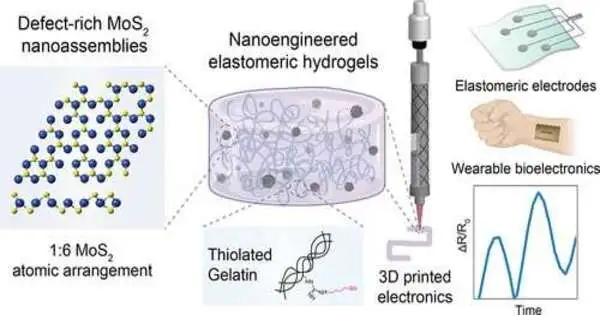

This biomaterial ink uses another class of 2D nanomaterials known as molybdenum disulfide (MoS2). The slim layered design of MoS2 contains deformity focuses to make it synthetically dynamic and, when joined with changed gelatin, to get an adaptable hydrogel, similar to the construction of Jell-O.

“These 3D-printed devices are very elastomeric, allowing them to be squeezed, bent, and twisted without breaking. Furthermore, because these devices are technologically active, they can detect dynamic human motion and pave the path for continuous motion monitoring.”

Kaivalya Deo, graduate student in the biomedical engineering department

“The effect of this work is broad in 3D printing,” said Akhilesh Gaharwar, academic partner in the Department of Biomedical Engineering and Presidential Impact Fellow. “This recently planned hydrogel ink is profoundly biocompatible and electrically conductive, preparing for the up and coming age of wearable and implantable bioelectronics.”

This study was recently distributed in ACS Nano.

The ink has shear-diminishing properties that decline in thickness as power increments, so it is strong inside the cylinder yet streams more like a fluid when crushed, like ketchup or toothpaste. The researchers combined these electrically conductive nanomaterials with modified gelatin to create a hydrogel ink with essential properties for designing 3D printing ink.

“These 3D-printed gadgets are very elastomeric and can be packed, bowed or wound without breaking,” said Kaivalya Deo, graduate understudy in the biomedical design division and lead creator of the paper. “Also, these gadgets are electronically dynamic, empowering them to screen dynamic human movement and prepare for nonstop movement checking.”

To 3D print the ink, scientists in the Gaharwar Laboratory planned a savvy, open-source, multi-head 3D bioprinter that is completely useful and adaptable, running on open-source devices and freeware. This also enables any analyst to assemble 3D bioprinters that are tailored to their specific testing requirements.

The electrically conductive 3D-printed hydrogel ink can make complex 3D circuits and isn’t restricted to planar plans, permitting analysts to make adaptable bioelectronics customized to patient-explicit necessities.

Using these 3D printers, Deo had the option to print electrically dynamic and stretchable electronic gadgets. These gadgets show uncommon strain-detecting abilities and can be utilized for designing adaptable checking frameworks. This likewise opens up additional opportunities for planning stretchable sensors with coordinated microelectronic parts.

One of the likely uses of the new ink is in 3D printing electronic tattoos for patients with Parkinson’s illness. Scientists imagine that this printed e-tattoo can screen a patient’s development, including quakes.

More information: Kaivalya A. Deo et al, Nanoengineered Ink for Designing 3D Printable Flexible Bioelectronics, ACS Nano (2022). DOI: 10.1021/acsnano.1c09386

Journal information: ACS Nano