The examination gathering of Teacher Kotohiro Nomura, Tokyo Metropolitan College, in collaboration with the exploration gathering of Chief Hiroshi Hirano, Osaka Exploration Establishment of Modern Science and Innovation, has created biobased polyesters from unappetizing plant assets, which can be effectively substance recyclable and show more promising mechanical properties in films than product plastics.

The work has been distributed in ACS Large-Scale Letters.

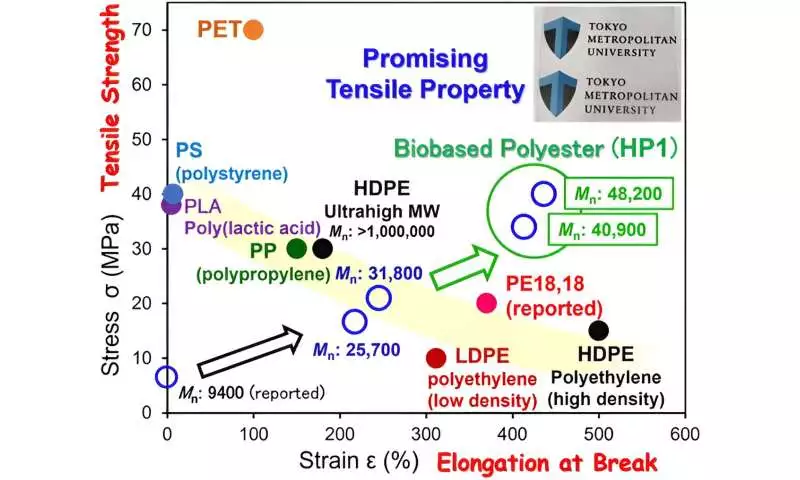

The improvement of superior execution and maintainable, recyclable plastics is significant for the production of a round economy. Bio-based polyesters produced using plant assets are supposed to turn into a promising option in contrast to item polymers, for example, polyethylene and polypropylene delivered from petrol. Nonetheless, there have not been many instances of the advancement of superior execution materials that surpass required mechanical properties like rigidity and lengthening at break.

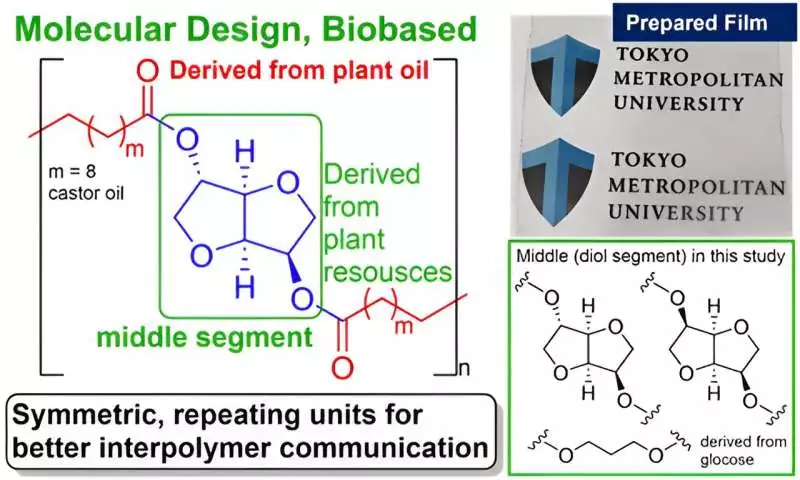

Combination techniques for high-subatomic-weight (long-chain) polymers have been a forthcoming issue in traditional polycondensation strategies. To settle this issue, the exploration group has fostered an olefin metathesis polymerization technique utilizing an elite presentation molybdenum impetus, zeroing in on polyesters derived from unappetizing plant assets.

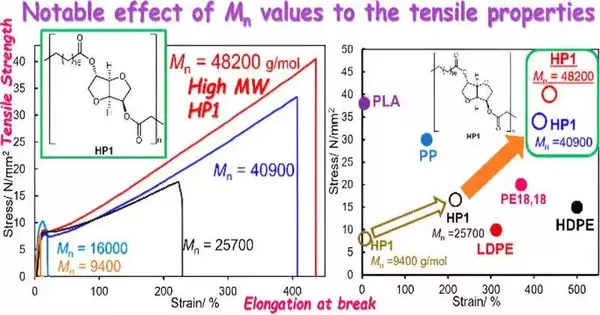

As a general rule, there is an antinomic connection between rigidity and lengthening at break in polymer film, as well as an expansion in the sub-atomic weight and the prolongation at break. Notwithstanding, the current polymer film shows that the malleable properties (strength and lengthening at break) of the polymer film expanded with the sub-atomic weight, displaying unrivaled properties compared to regular plastics.

Credit: JST

This technique is the primary outcome of fostering biobased polyester materials that can be deteriorated or reused. The film properties can be additionally improved by joining the material with normally inferred filaments like cellulose nanofibers.

Olefin metathesis polymerization technique

“Olefin” is a general term for hydrocarbons with one carbon-twofold bond. “Metathesis” signifies “replacement.” In this manner, the recombination response of substituents as soon as possible is the obligation of an olefin, known as the olefin metathesis response. For instance, there is a response where a carbon twofold bond in an olefin is supplanted with a synergist metal-carbon twofold bond (a chemically dynamic species) through the response utilizing a reactant metal like ruthenium or molybdenum.

Basic design, structure of present biobased polyesters Basic structure, framework in the present biobased polyesters derived from plant oil and glucose (in this study). The present polymers can be easily decomposed to the monomer units by chemical recycle simply using treating with alcohols (called catalytic transesterification). Credit: JST.

The polymer union technique utilizing such a response is known as the olefin metathesis polymerization strategy. The current strategy created by the scientists is a polycondensation blending polymer that delivers ethylene as a result (non-cyclic diene metathesis polymerization).

More information: Mika Kojima et al, Synthesis of High Molecular Weight Biobased Aliphatic Polyesters Exhibiting Tensile Properties Beyond Polyethylene, ACS Macro Letters (2023). DOI: 10.1021/acsmacrolett.3c00481