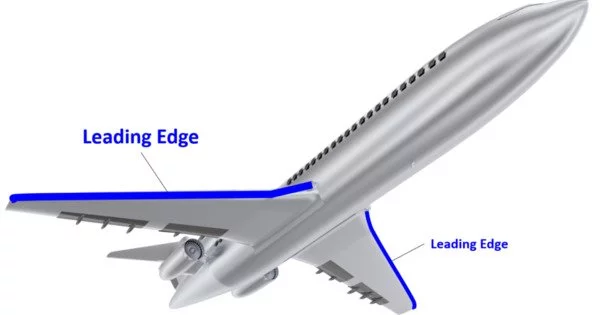

To combat the hazards of ice, a mechanical engineer has developed a sprayable ice-shedding material that is 100 times stronger than any other. It’s been tested by Boeing under erosive rain conditions at 385 miles per hour and outperformed current state-of-the-art aerospace coating technologies.

A University of Houston mechanical engineer has developed a sprayable ice-shedding material that is 100 times stronger than any others. The new durable coating material has been tested by Boeing under erosive rain conditions at 385 miles per hour and has outperformed current state-of-the-art aerospace coating technologies.

The principle of the new “fracture-controlled material” lies in the fact that for detachment of any external solid object from a surface (like ice from an airplane wing), force must be applied, and that force will inevitably lead to the formation of some cracks at the interface. These cracks, or fractures, grow until full detachment of the object from the surface.

Through a new concept developed by Hadi Ghasemi, Cullen Associate Professor of Mechanical Engineering, detachment can be accurately controlled and accelerated.

We developed a new concept in which, through material design, you can significantly accelerate the crack formation and growth and easily remove external objects from the surface. This concept is implemented to develop materials that are highly durable, and ice does not attach to these materials. Fracture-controlled surfaces provide a rich material platform to guide future innovation of materials with minimal adhesion while having very high durability,

Sina Nazifi

“We developed a new concept in which, through material design, you can significantly accelerate the crack formation and growth and easily remove external objects from the surface. This concept is implemented to develop materials that are highly durable, and ice does not attach to these materials,” reports Ghasemi in the cover article of Materials Horizons. Ghasemi’s research team includes his doctoral student, Sina Nazifi. “Fracture-controlled surfaces provide a rich material platform to guide future innovation of materials with minimal adhesion while having very high durability,” said Ghasemi.

A necessary solution

From 1990 to 2000, 12% of all weather-related air disasters were due to icing. In the power industry, icing in transmission systems can lead to a collapse of poles and towers, rupture of conductors, and flashover of insulators.

To combat the dangers of icing, a wide range of materials with ice-shedding characteristics have been developed, but many tend to have very low durability, limiting their effectiveness.

“The primary challenge in developing ice-shedding materials is finding materials with both low ice adhesion and good durability,” said Ghasemi.

His new material offers both.

This new fundamental concept of fracture-controlled materials paves the way for innovations in materials for aerospace, wind energy, and other industrial and commercial applications where icing is an issue. Ice buildup on wind turbines could lead to an 80% drop in power generation which could be avoided through these new coating materials, according to the researchers.