Roused by the construction of muscles, an imaginative new procedure for making fiber actuators could prompt advances in mechanical technology, prosthetics, and savvy clothing, as per a Penn State-driven group of researchers who found the cycle.

“Actuators are any material that will change or distort under any outside improvements, similar to parts of a machine that will align, twist, or extend,” said Robert Hickey, collaborator teacher of materials science and design at Penn State. Also, for advances like mechanical technology, we want to foster delicate, lightweight adaptations of these materials that can fundamentally go about as fake muscles. Our work is truly about tracking down a better approach to doing this.

“This is a vast subject, and there’s a lot of intriguing research out there, but it’s mainly focused on designing materials to optimize attributes. What excites us about our work is that we truly focus on the relationship between chemistry, structure, and property.”

Robert Hickey, assistant professor of materials science and engineering at Penn State

The group fostered a two-venture cycle to make fiber actuators that emulate the construction of muscle filaments and that succeed in a few perspectives compared with other current actuators, remembering for proficiency, incitation strain, and mechanical properties. They announced their discoveries today (June 2) in the journal Nature Nanotechnology.

“This is a major field and there’s a ton of invigorating exploration out there,” Hickey said. “However, it has been truly centered around designing materials to improve properties,” Hickey said. “What makes our work energizing is that we truly center around the association between science, construction, and property.”

Hickey recently led a group that delivered self-collecting, nanostructured hydrogel materials. Hydrogels are organizations of polymers that can grow and hold a lot of water while keeping up with their construction.

In the new exploration, the researchers found that strands made of this hydrogel material can extend a few times their unique length when hydrated and solidify and secure in the stretched shape when dried in the drawn-out state. Adding water or intensity permits the material to snap back to its unique size, making it promising for use as an actuator, the researchers said.

“We began to perceive these strands were contracting and showing a few truly interesting properties,” Hickey said. “At the point when we began portraying the design, we understood that there was some, on a very basic level, fascinating stuff happening here. What’s more, we began perceiving that in numerous ways, the design of these impersonated or reflected normal muscle.”

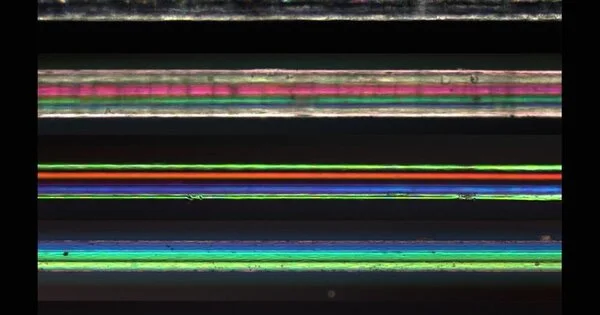

The materials comprise exceptionally adjusted nanoscale structures with exchanging glasslike and undefined areas, looking like the arranged and striated example of mammalian skeletal muscle, the researchers said.

The extraordinary extending properties of the hydrogels are a consequence of the mix of unbending nebulous nanoscale spaces and micrometer-scale pores loaded up with water. At the point when the hydrogels are extended, they snap back like an elastic band. In the event that the extended filaments are dried in the drawn-out express, the polymer organization will solidify, securing the lengthened state of the strands.

“We consider one of the central reasons we have these outstanding properties is that the filaments are coordinated definitively at the nanometer scale, comparable to the sarcomere of a human muscle,” Hickey said. “What’s going on is you have a uniform withdrawal.” These formless spaces are completely coordinated exactly along with the fiber, and that implies they contract in a solitary heading, which leads to this capacity to return to that unique state. “

Applying water or intensity to the extended materials softens the gems and permits the material to get back to its unique structure. When extended to multiple times its unique length, the material can get back to inside 80% of its size and can do this over many cycles without execution decline, the researchers said.

“The way that we can utilize two distinct boosts, intensity and water, to set off activation opens up twofold the opportunities for materials made with this strategy,” Hickey said. Most actuators are set off by a solitary improvement. Double boosts open up the flexibility of our materials. “