Researchers at the U.S. Department of Energy’s (DOE) Brookhaven Public Research Center have effectively shown the way that independent techniques can find new materials. The computerized reasoning (man-made intelligence)-driven method prompted the disclosure of three new nanostructures, including a first-of-its-kind nanoscale “stepping stool.” The examination was distributed today in Science Advances.

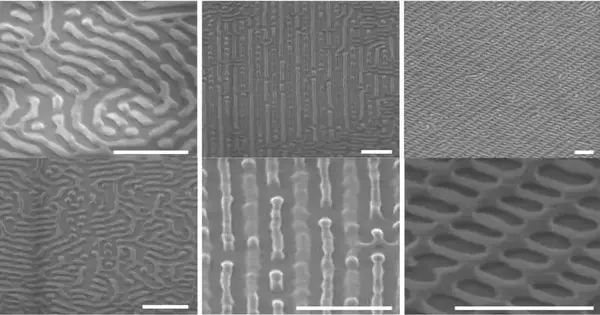

The newfound designs were framed by a cycle called “self-get together,” in which a material’s particles coordinate themselves into exceptional examples. Researchers at Brookhaven’s Center for Utilitarian Nanomaterials (CFN) are seasoned veterans of coordinating the self-gathering process, making layouts for materials to frame beneficial plans for applications in microelectronics and catalysis, and that’s only the tip of the iceberg. Their disclosure of the nanoscale stepping stool and other new designs further enlarges the extent of self-gathering’s applications.

“Self-assembly can be employed as a technique for nanopatterning, which is driving breakthroughs in microelectronics and computer technology.”

CFN scientist and co-author Gregory Doerk.

“Self-gathering can be utilized as a method for nanopatterning, which is a driver for propelling microelectronics and PC equipment,” said CFN researcher and co-creator Gregory Doerk. “These advances are continuously pushing for higher goals while utilizing more modest nanopatterns.” You can get tiny and firmly controlled highlights from self-collecting materials; however, they aren’t guaranteed to submit to the sort of aging that we spread out for circuits, for instance. “By coordinating our efforts and utilizing a layout, we can shape more valuable designs.”

Staff researchers at CFN, which is a DOE Office of Science Client Office, intend to construct a library of self-gathered nanopattern types to widen their applications. In past examinations, they showed that new kinds of examples are made conceivable by mixing two self-gathering materials in one place.

“The way that we can now make a stepping-stool structure, which nobody has at any point longed for, is astonishing,” said CFN bunch pioneer and co-creator Kevin Yager. “Conventional self-gathering can frame somewhat straightforward designs like chambers, sheets, and circles. However, by combining two materials and utilizing the best compound grinding, we’ve discovered that entirely new designs are possible.”

Mixing self-gathered materials in one place has empowered CFN researchers to reveal novel designs, but it has likewise created new difficulties. With a lot more boundaries to control in the self-gathering process, tracking down the right mix of boundaries to make new and helpful designs is a fight against time. To speed up their examination, CFN researchers utilized another man-made intelligence ability: independent trial and error.

In a joint effort with the Middle for Cutting Edge Math for Energy Exploration Applications (CAMERA) at DOE’s Lawrence Berkeley Public Research Center, Brookhaven researchers at CFN and the Public Synchrotron Light Source II (NSLS-II), one more DOE Office of Science Client Office at Brookhaven Lab, have been fostering an artificial intelligence structure that can independently characterize and play out every one of the means of an examination. CAMERA’s gpCAM calculation drives the structure’s independent navigation. The group’s most recent exploration is its most memorable and effective showing of its capacity to find new materials.

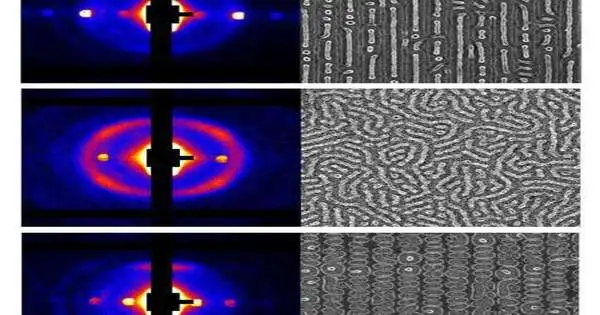

X-beams dispersing information (left) are displayed close by by relating and examining electron microscopy pictures (right) of key regions in the example recognized by the man-made intelligence calculation. The pictures uncovered three novel nanopatterns: rotating lines (top), slant (focus), and stepping stool (base). The scale bar is 500 nanometers.

“gpCAM is an adaptable calculation and programming system for independent trial and error,” said Berkeley Lab researcher and co-creator Marcus Noack. “It was utilized especially shrewdly in this review to independently investigate various elements of the model.”

“With assistance from our associates at Berkeley Lab, we had this product and system all set, and presently we’ve effectively utilized it to find new materials,” Yager said. “We’ve currently learned sufficient about independent science that we can take a materials issue and convert it into an independent issue quite easily and without any problem.”

To speed up materials disclosure utilizing their new calculation, the group initially fostered a mind-boggling test with a range of properties for investigation. Analysts created the example utilizing the CFN nanofabrication office and did the self-get-together in the CFN material amalgamation office.

“An outdated approach to doing material science is to orchestrate an example, measure it, gain from it, and then return and make an alternate example and continue to repeat that interaction,” Yager said. “All things being equal, we made an example that has a slope for each and every boundary we’re keen on.” “That single example is thus a huge assortment of numerous unmistakable material designs.”

Then, the group carried the example to NSLS-II, which produces ultrabright X-beams for concentrating on the construction of materials. CFN operates three trial stations in conjunction with NSLS-II, one of which, the Delicate Matter Connection Points (SMI) beamline, was used in this review.

“One of the SMI beamline’s assets is its capacity to zero out the X-beam pillar, for example, down to microns,” said NSLS-II researcher and co-creator Masa Fukuto. “By dissecting how these microbeam X-beams get dissipated by the material, we find out about the material’s neighborhood structure at the enlightened spot.” Estimations at a wide range of spots can then uncover how the nearby design changes across the inclination test. In this work, we let the simulated intelligence calculation pick, on the fly, which spot to gauge closely to augment the worth of every estimation.

As the example was estimated at the SMI beamline, the calculation, without human intercession, was based on a model of the material’s various and different arrangements of designs. The model refreshed itself with each resulting X-beam estimation, making each estimation more astute and exact.

The Delicate Matter Points of Interaction (SMI) beamline at the Public Synchrotron Light Source II.

Very quickly, the calculation had identified three critical regions in the complicated example for the CFN scientists to concentrate on more intently. They utilized the CFN electron microscopy office to picture those critical regions with dazzling subtlety, uncovering the rails and rungs of a nanoscale stepping stool, among other novel highlights.

From beginning to end, the analysis took around six hours. Using conventional techniques, the scientists estimated that it would have taken about a month to make this discovery.

“Independent strategies can enormously speed up revelation,” Yager said. “It’s basically ‘fixing’ the standard revelation circle of science, so we cycle among speculations and estimations all the more rapidly.” Past speed notwithstanding, independent strategies increment the extent of what we can study, meaning we can handle really testing science issues.

“Pushing ahead, we need to examine the intricate interaction among various boundaries.” “We led recreations utilizing the CFN PC bunch that checked our exploratory outcomes, yet they additionally proposed how different boundaries, like film thickness, can likewise assume a significant role,” Doerk said.

The group is effectively applying their independent examination strategy to many material revelation issues in self-gathering as well as different classes of materials. Independent disclosure strategies are versatile and can be applied to almost any exploration issue.

“We are currently conveying these techniques to the expansive local area of clients who come to CFN and NSLS-II for lead tests,” Yager said. “Anybody can work with us to speed up the investigation of their materials research.” “We predict this will enable a large group of new revelations before very long, remembering that the public needs regions like clean energy and microelectronics.”

More information: Gregory S. Doerk et al, Autonomous discovery of emergent morphologies in directed self-assembly of block copolymer blends, Science Advances (2023). DOI: 10.1126/sciadv.add3687. www.science.org/doi/10.1126/sciadv.add3687

Journal information: Science Advances