A group of Florida State University scientists has revealed a method for utilizing low-energy light to control photopolymers or plastic films—a finding that has suggestions for many innovations that utilize light as an energy source to make shape-moving designs.

The examination is distributed in the journal ACS Applied Polymer Materials and is a joint work by Associate Professors of Chemistry and Biochemistry Ken Hanson and Justin Kennemur and FAMU-FSU College of Engineering Professor William Oates.

“The thought is that we need to bridle low-energy light and produce mechanical power as effectively as could be expected,” Hanson said.

“When exposed to high-energy ultraviolet light, many polymers have stability restrictions that cause slow breakdown. Using lower-energy visible light is a fantastic approach to get around this problem.”

Justin Kennemur

Analysts overall have been dealing with materials that answer outer boosts like light, temperature, attractive fields or power. These boosts can make a material change its shape, its sub-atomic plan or its mechanical properties and have been used in research in advanced mechanics, aviation design, drug conveyance, and that’s just the beginning.

FSU’s examination group has been especially keen on light-responsive frameworks for mechanical work, a less-concentrated area.

So far, research in that space has shown that the use of light for this design is frequently vigorously wasteful and requires high-energy light for huge outcomes. Hanson, Kennemur, and Oates believed that their combined skills—Hanson specializes in solar cells, Kennemur in polymer blends, and Oates in material portrayal and displaying—could aid them in developing a clever methodology.

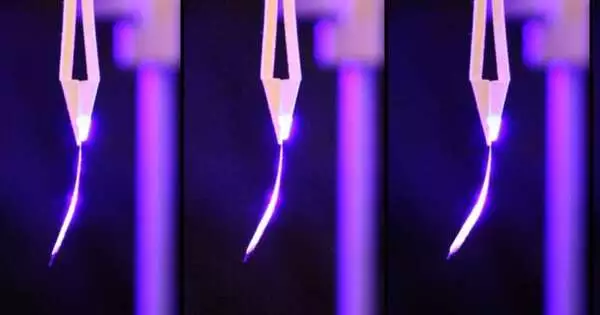

Their examination group at last teamed up on another cycle that really reaps low-energy light and uses it to twist plastic movies about the thickness of Scotch tape.

“Numerous polymers have security limits that result in sluggish debasement when presented to high-energy bright light,” Kennemur said. “Utilizing lower-energy noticeable light is an incredible method for evading this issue.”

The FSU group tried different things with a photopolymer in view of the synthetic compound stilbene. Stilbene without anyone else has restricted applications, yet making colors, optical brighteners, or color lasers can be utilized. Hanson, Kennemur, and Oates applied a system called a trio sensitizer to the polymer that permitted it to absorb the low-energy light and convert it into high-energy mechanical work.

When the examination group focused a low light on the stilbene-based plastic movies, they saw the movies twist because of the energy move.

“It is striking how, interestingly, low-energy photons can control stilbene to exactly control the state of a polymer with energized light,” Oates said.

Considering this evidence of idea, the scientists intend to refine this cycle further later on, utilizing an assortment of polymer structures, light-retaining nanostructures, and high-level displaying devices.

Different supporters of this paper are FSU understudies Drake Beery, Eugenia Stanisauskis, Grace McLeod, Gina Guillory, and postdoctoral analyst Anjan Das.

More information: Drake Beery et al, Enabling Lower Energy Light Harvesting in Stilbene-Based Photomechanical Polymers via Triplet Sensitization, ACS Applied Polymer Materials (2022). DOI: 10.1021/acsapm.2c00660