It is possible to convert plastic and greenhouse gases into sustainable fuels using a solar-powered system. This process is called “plastic to fuel” or “PTF” and it involves using a thermal conversion process to convert plastic and other waste materials into synthetic crude oil. This oil can then be refined into various types of fuels such as gasoline, diesel, and jet fuel. Additionally, some systems capture CO2 from the air and combine it with hydrogen to produce hydrocarbons, which can be used as sustainable fuels. However, it is important to note that these processes are currently in the early stages of development and may not yet be economically viable on a large scale.

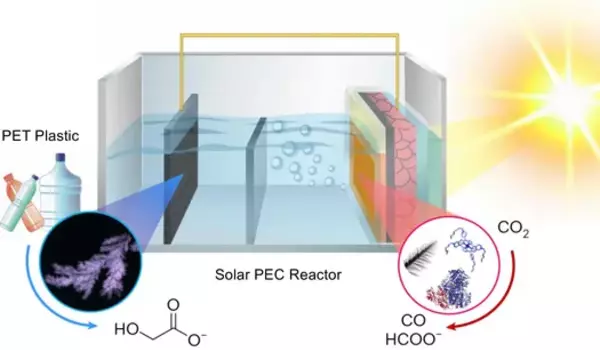

Researchers have created a system that can convert plastic waste and greenhouse gases into sustainable fuels and other valuable products using only solar energy. The system, developed by researchers from the University of Cambridge, can convert two waste streams into two chemical products at the same time, which is the first time this has been accomplished in a solar-powered reactor.

The reactor converts carbon dioxide (CO2) and plastics into a variety of products that can be used in a variety of industries. CO2 was converted into syngas, a key component of sustainable liquid fuels, and plastic bottles were converted into glycolic acid, which is widely used in the cosmetics industry, in tests. The system can easily be tuned to produce different products by changing the type of catalyst used in the reactor.

Converting plastics and greenhouse gases – two of the biggest threats facing the natural world – into useful and valuable products using solar energy is an important step in the transition to a more sustainable, circular economy. The results are reported in the journal Nature Synthesis.

A solar-powered technology that can help address both plastic pollution and greenhouse gas emissions at the same time could be a game changer in the development of a circular economy.

Subhajit Bhattacharjee

“Converting waste into something useful using solar energy is a major goal of our research,” said Professor Erwin Reisner from the Yusuf Hamied Department of Chemistry, the paper’s senior author. “Plastic pollution is a huge problem worldwide, and often, many of the plastics we throw into recycling bins are incinerated or end up in landfill.”

Reisner is also the director of the Cambridge Circular Plastics Centre (CirPlas), which aims to eliminate plastic waste by combining big ideas with practical solutions. Other solar-powered’recycling’ technologies show promise for addressing plastic pollution and lowering greenhouse gas levels in the atmosphere, but they have yet to be combined in a single process.

“A solar-powered technology that can help address both plastic pollution and greenhouse gas emissions at the same time could be a game changer in the development of a circular economy,” said co-first author Subhajit Bhattacharjee. “We also need something that’s tuneable, so you can easily make changes depending on the final product you want,” co-first author Dr. Motiar Rahaman said.

The scientists created an integrated reactor with two distinct compartments: one for plastic and one for greenhouse gases. The reactor employs a perovskite-based light absorber, which is a promising alternative to silicon for next-generation solar cells.

The team created various catalysts, which were then incorporated into the light absorber. The researchers could change the end product by changing the catalyst. Under normal temperature and pressure conditions, tests of the reactor revealed that it could efficiently convert PET plastic bottles and CO2 into different carbon-based fuels such as CO, syngas, or formate, in addition to glycolic acid. The Cambridge reactor produced these products at a much faster rate than conventional photocatalytic CO2 reduction processes.

“Generally, CO2 conversion requires a lot of energy, but with our system, basically you just shine a light at it, and it starts converting harmful products into something useful and sustainable,” said Rahaman. “Prior to this system, we didn’t have anything that could make high-value products selectively and efficiently.”

“What’s so special about this system is the versatility and tuneability — we’re making fairly simple carbon-based molecules right now, but in the future, we could be able to tune the system to make far more complex products, just by changing the catalyst,” said Bhattacharjee.

The European Research Council recently awarded Reisner new funding to aid in the development of their solar-powered reactor. They hope to improve the reactor over the next five years so that it can produce more complex molecules. According to the researchers, similar techniques could one day be used to create an entirely solar-powered recycling plant.

“Developing a circular economy, in which we make useful things from waste rather than throwing it away, is critical if we are to meaningfully address the climate crisis and protect the natural world,” Reisner said. “And using the Sun to power these solutions means we’re doing it cleanly and sustainably.”