Mineral oil greases shield motor parts from wear, and this impact is improved by adding polymer nanoparticles to the greasable oil. A UK group has now found that the epoxy functionalization of these nanoparticles further advances erosion reduction on metal surfaces.

As the group reports in the journal Angewandte Chemie, nanoparticles containing epoxy bunches stick firmly to treated steel surfaces, which prompts a huge decrease in contact.

Car engines with heavily greased up parts use less fuel, produce lower outflows, and have less long-term wear.Mineral oil is widely used as an oil, and nanoparticles can be easily prepared within this dissolvable using a technique known as polymerization-incited self-gathering.Covering the outer layer of the metal parts with nanoparticles a couple dozen millionths of a millimeter in size shields them from direct contact.

“Amazingly, the adsorbed nanoparticles stayed intact on the stainless steel surface following such studies, which were carried out at the average working temperature of an internal combustion engine,”

Steve Armes at the University of Sheffield (UK)

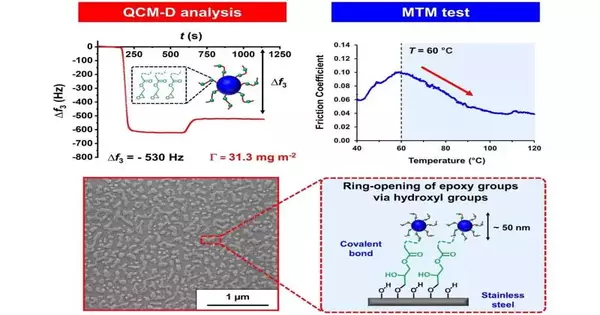

Csilla György and Steve Armes at the College of Sheffield (UK) planned “busy” nanoparticles involving oil-solvent poly (lauryl methacrylate) chains and an oil-insoluble nanoparticulate center. These nanoparticles were made to adhere firmly to metal surfaces by bringing epoxy bunches into the “hairs” by copolymerizing lauryl methacrylate with glycidyl methacrylate, an epoxy-useful monomer.

The researchers discovered that the epoxy-containing nanoparticles reacted with hydroxyl gatherings on the treated steel’s outer layer.This response prompted a solid bond between the nanoparticles, a peculiarity known as compound adsorption. Regardless of whether compound adsorption happened, it depended upon the exact area of the epoxy gatherings. “Shockingly, introducing a much greater number of epoxy bunches into the nanoparticle centers made no useful difference,” Armes explains.

The adsorbed nanoparticles decreased grating altogether, as the Sheffield group found while leading tribological concentrates as a team with researchers at Lubrizol, a motor oil-added substances organization situated in the UK. “Amazingly, the adsorbed nanoparticles stayed in one piece on the treated steel surface after such tests, which were conducted at the common working temperature of a gas-powered motor,” Armes adds.

Such epoxy-functionalized nanoparticles could hence mean a further jump in execution for oil-added substances in cutting-edge motor oil plans.

More information: Csilla György et al, Enhanced Adsorption of Epoxy‐Functional Nanoparticles onto Stainless Steel Significantly Reduces Friction in Tribological Studies, Angewandte Chemie International Edition (2023). DOI: 10.1002/anie.202218397