Specialists from North Carolina State University have fostered another strategy for extricating hydrogen gas from fluid transporters that is quicker, more affordable, and more energy efficient than past methodologies.

Milad Abolhasani, the author of a paper on the new method and an academic partner in synthetic and biomolecular design at NC State, says there are a few specialized impediments that must be overcome before it can be considered a viable alternative to current advances.”One of the enormous obstructions to the reception of a hydrogen economy is the expense of capacity and transportation.”

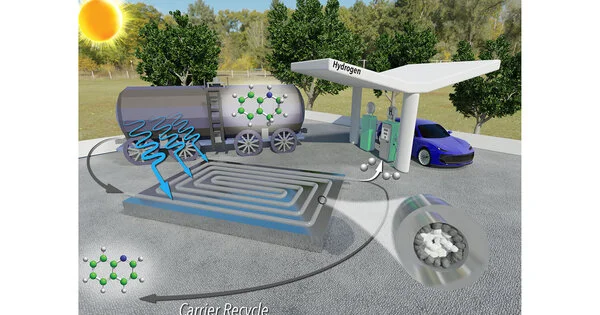

Hydrogen fuel doesn’t bring about CO2 outflows. Furthermore, hydrogen refueling stations could be situated at existing corner stores, exploiting existing foundations. Yet, moving hydrogen gas is risky, so hydrogen should be shipped by means of a fluid transporter. A vital impediment for this procedure is that removing hydrogen from the fluid transporter at objective locales, like power stations, is energy-consuming and costly.

“In a traditional batch reactor, titanium oxide makes up 99 percent of the photocatalyst and rhodium makes up 1%. We just need 0.025 percent rhodium in our continuous flow reactor, which saves a lot of money in the long run. A gram of rhodium can cost upwards of $500.”

Milad Abolhasani, an associate professor of chemical and biomolecular engineering at NC State.

“Past examination has shown that it is feasible to utilize photocatalysts to deliver hydrogen gas from a fluid transporter utilizing just daylight,” Abolhasani says. “In any case, existing strategies for doing this were difficult, tedious, and required a lot of rhodium—a metal that is over the top expensive.”

Malek Ibrahim, the first creator of the paper and a previous postdoctoral specialist at NC State, says “We’ve fostered a method that applies a reusable photocatalyst and daylight to extricate hydrogen gas from its fluid transporter all the more rapidly and while utilizing less rhodium—making the whole cycle fundamentally more affordable.” Likewise, the main products are hydrogen gas and the fluid transporter itself, which can be reused over and over again. It’s entirely practical. “

One key to the progress of the new procedure is that it is a nonstop stream reactor. The reactor looks like a dainty, clear cylinder loaded with sand. The “sand” comprises micron-scale grains of titanium oxide, a significant number of which are covered with rhodium. The hydrogen-conveying fluid is siphoned into one end of the cylinder. The rhodium-covered particles line the external piece of the cylinder, where daylight can contact them. These particles are photoreactive impetuses that, within the sight of daylight, respond to the fluid transporter to deliver hydrogen atoms as a gas.

The analysts exactly designed the framework so just the external grains of titanium oxide are covered with rhodium, guaranteeing the framework utilizes no more rhodium than is needed.

“In a regular group reactor, the vast majority of the photocatalyst is titanium oxide and 1% is rhodium,” Abolhasani says. “In our ceaseless stream reactor, we just have to utilize 0.025% rhodium, which has a major effect on the last expense. “A solitary gram of rhodium costs more than $500.”

In their model reactor, the scientists had the option to accomplish a close to 100% yield — implying that the vast majority of the hydrogen particles were set free from the fluid transporter — in three hours.

“That is multiple times quicker than regular cluster reactors, which require 24 hours to arrive at close to 100% yield,” Ibrahim says. “Also, the framework ought to be easy to increase or scale out to consider impetus reuse on a business scale—you can basically make the cylinder longer or consolidate numerous cylinders running in equal.”

The stream framework can run consistently for as long as 72 hours before its productivity diminishes. As of now, the impetus can be “recovered” without removing it from the reactor — it’s a basic cleaning process that requires around six hours. The framework can then be restarted and run at full effectiveness for an additional 72 hours.

NC State has recorded a temporary patent for the innovation.

The examination was distributed in the ChemSusChem diary.