A college of twenty scientists prevailed in the fast creation of tiny “antibubbles.” Previous methods for delivering these fluid drops surrounded by an air layer either required controllability or were prone to stopping and being much slower.The group of analysts has as of late distributed their discoveries in the diary, Progressed Materials.

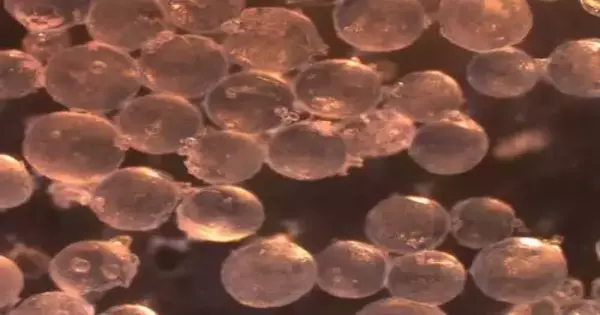

Antibubbles smaller than one millimeter in diameter have a wide range of applications, including the food and pharmaceutical industries.Their hydrophobic yet permeable shell gives the antibubbles an external air layer for additional security. Together, the two layers can keep the antibubble intact for a few days.

“With ultrasound, we can break the hydrophobic shell at a particular second, after which the antibubble discharges its substance.” This is, for instance, helpful for the controlled arrival of medications at explicit areas inside the body, which makes sense to the first creator, Jieke Jiang.

“We may use ultrasound to breach the hydrophobic shell at a specified point, allowing the antibubble to release its material. This is important for the regulated delivery of medications at specific places throughout the body, for example.”

First author Jieke Jiang.

To make these helpful microparticles, the scientists fostered another idea in which a spout is flying through a fluid layer (JetALL). Jiang makes sense of, “We planned and 3D-printed a little, cone-molded supply that holds the fluid layer.” The cone is large enough to prevent stopping up but small enough to keep the layer intact due to surface strain.The fluid layer is a suspension of silica nanoparticles that frames the external hydrophobic shell. This shell settles the air layer that frames the antibubbles.

“Antibubbles”—gathering cases—and the activity of JetALL.

The new strategy is fast; it creates microcapsules at stream rates up to 3,000 cases per second. The cases are basically the same size. Jiang said, “We estimated them to be all between 100 and 150 micrometers for one of the examples.”

Other biodegradable materials, for example, polylactic acid (PLA), could likewise be utilized as a defensive shell rather than the air layer. This capability opens up incredible opportunities for the use of medication conveyance, where you must precisely determine the appropriate portion of medication.

More information: Jieke Jiang et al, High‐Throughput Fabrication of Size‐Controlled Pickering Emulsions, Colloidosomes and Air‐Coated Particles via Clog‐Free Jetting of Suspensions, Advanced Materials (2023). DOI: 10.1002/adma.202208894